Full Glass vs Half Glass Doors: What’s Best for Your Mid-Missouri Home?

Full Glass vs Half Glass Doors: What’s Best for Your Mid-Missouri Home?

Your entry door does more than welcome guests. It handles Mid-Missouri’s humid summers, bitter winter wind chills, and everything in between. Full glass or half glass? The right choice depends on your home’s style, how much privacy you need, and where the door faces.

This guide breaks down the key differences so you can choose confidently for your Columbia, Jefferson City, or Lake of the Ozarks home.

Key Takeaways

- Full glass doors maximize natural light and outdoor views, while half glass doors balance privacy, security, and style—both work well in Mid-Missouri homes when matched to the right location.

- In Columbia, Jefferson City, and Lake of the Ozarks, your choice depends on weather exposure, how much privacy you need, and whether your home leans traditional or contemporary.

- Modern full and half glass doors can both be energy efficient when built with insulated glass, low e coatings, and proper weatherstripping—cheap single-pane options are a poor fit for our climate.

- Security comes from tempered or laminated safety glass, quality hardware, and professional installation, not simply from having less glass surface.

- CoMo Premium Exteriors can evaluate your existing openings and provide a free estimate to compare full glass vs half glass options for your specific entry door or patio doors.

What Is a Full Glass Door vs a Half Glass Door?

When homeowners across Columbia and surrounding Mid-Missouri communities start thinking about door replacement, one of the first decisions is how much glass you actually want. Let’s walk through what these terms mean in plain language so you can understand your options.

Full glass doors (sometimes called “full-lite” doors) have glass panels that cover nearly the entire door slab. You’ll see these frequently on patio doors leading to decks, side entries that need extra light, and contemporary front doors on newer homes. Think of a sleek fiberglass entry door with a large clear or decorative glass panel running top to bottom—that’s full glass.

Half glass doors (or “half-lite” doors) feature glass in the upper half or upper third of the door, with a solid panel covering the bottom portion. These are extremely common on traditional front doors and back doors throughout Columbia, Jefferson City, and Boonville, especially in homes built from the 1960s through the 2000s. The solid lower section provides privacy and a more classic appearance.

Here’s what both types have in common:

- Available in fiberglass, steel, or wood materials

- Can use single, double, or triple-pane insulated glass

- Compatible with low e glass coatings for better energy performance

- Work with a variety of frame colors and hardware finishes

This article focuses specifically on exterior doors—front doors, side entries, and patio doors—rather than interior French doors or room dividers.

Pros and Cons of Full Glass Doors

Full glass doors make a statement, but they’re not the right fit for every home or every opening. Here’s what Mid-Missouri homeowners should consider when weighing this option against our hot summers, freezing winters, and occasional hail and wind storms.

Benefits of Full Glass Doors

- Maximum natural light: Full glass brings the most daylight into entryways, making dark foyers feel warm and inviting.

- Clear views: Perfect for showcasing landscaping, watching kids play in the backyard, or enjoying Lake of the Ozarks scenery.

- Connection to outdoors: Creates a seamless visual link between inside and decks or patios, making both spaces feel larger.

- Modern curb appeal: Fits contemporary, lake home, and modern farmhouse aesthetics that buyers in our region appreciate.

- Space enhancement: Helps smaller Columbia ranch homes feel more open and less closed-in.

- Practical visibility: Great for keeping an eye on pets or watching for deliveries without opening the door.

Drawbacks to Consider

- Reduced privacy: Clear full glass means neighbors and passersby can see into your entryway, especially at night when interior lights are on.

- More visible smudges: Fingerprints, dog nose prints, and water spots show more readily on larger glass surfaces.

- May require window treatments: Many homeowners add blinds, shades, or built-in blinds to manage light and privacy.

- Energy considerations: Larger glass surface area can gain or lose more heat if you’re not using high-quality insulated glass.

Performance Notes

Full glass doors must use tempered or laminated safety glass to protect your family. The frames and weatherstripping need proper installation to handle Mid-Missouri wind and driving rain. When a local contractor like CoMo Premium Exteriors handles the install, we mitigate performance concerns by using insulated glass units with low e coatings and ensuring frames are correctly flashed and sealed.

Pros and Cons of Half Glass Doors

Half glass doors hit a middle ground that appeals to many homeowners across Columbia, Ashland, and Moberly. They’re especially popular on traditional and farmhouse-style homes where privacy and style both matter.

Benefits of Half Glass Doors

- Better privacy: The solid lower half prevents people from seeing the full interior, which matters on busy streets or close-together neighborhoods.

- Style flexibility: Works beautifully with Craftsman, colonial, ranch, and farmhouse architectural styles common in our region.

- Easier pairing with sidelights: Combines naturally with glass sidelights or transoms for added light without sacrificing the door’s privacy.

- More interior wall space: Leaves room behind the door for coat hooks, benches, or furniture in the entry.

- Perceived security: More solid surface area can feel more secure, and there’s more space for additional deadbolts or smart locks.

- Hides wear and tear: The solid lower section doesn’t show scuffs from shoes, kids, or pets the way full glass would.

Energy and Performance

Less glass surface can slightly reduce heat transfer compared to a similar full glass door—but don’t get too caught up in this detail. The quality of the door slab, the insulation value of the glass package, and the weatherstripping installation are far more important than glass height alone. A well-built half glass door with double-pane insulated glass will outperform a cheap full glass door every time.

Trade-offs

- Less natural light enters through the door compared to full glass options.

- Smaller view of your porch, yard, or outdoor space.

- May look more “traditional” than you want if you’re aiming for an ultra-modern remodel.

The good news: decorative glass options like frosted, obscure, or textured patterns let you bring in light while maintaining privacy—useful on those busy Columbia streets or close-together Lake condo units.

Comparing Light, Privacy, and Curb Appeal

Most homeowners start with two questions: “How much light do I want coming through this door?” and “How much do I want people to see inside?” Let’s walk through how full and half glass doors answer those questions differently.

Light Considerations

|

Door Type |

Light Level |

Best For |

|---|---|---|

|

Full Glass |

Maximum daylight |

North-facing entries, shaded lots, dark foyers |

|

Half Glass |

Moderate daylight |

Typical Mid-Missouri entryways with some window light nearby |

Full glass doors are ideal when you need to enhance a space that doesn’t get much light otherwise. Half glass doors work well when the entry already has sidelights or when you don’t want the entry to feel like a fishbowl.

Privacy Factors

- Full glass with clear panels: Minimal privacy during the day, almost none at night when lights are on inside.

- Full glass with frosted/textured/tinted options: Moderate privacy while still allowing plenty of light to enter.

- Half glass with clear upper panel: Good privacy since only the upper portion is visible.

- Half glass with obscure glass or built-in blinds: Strong privacy with flexible light control.

Curb Appeal and Home Style

Your door should fit your home’s overall look. Here’s a quick guide:

- Full glass fits well with: Contemporary new builds, remodeled 1970s–1980s homes with updated exteriors, lake homes, modern farmhouse designs.

- Half glass complements: Classic brick-front Columbia neighborhoods from the 1990s–2010s, older central Columbia homes with front porches, farmhouses across rural Boone and Callaway Counties.

Design tips to consider:

- Pair full glass with sidelights or decorative grids for a stylish main entry.

- Use half glass with Craftsman-style panels for traditional front doors.

- Coordinate your door style with existing windows, siding, and porch details for a cohesive exterior.

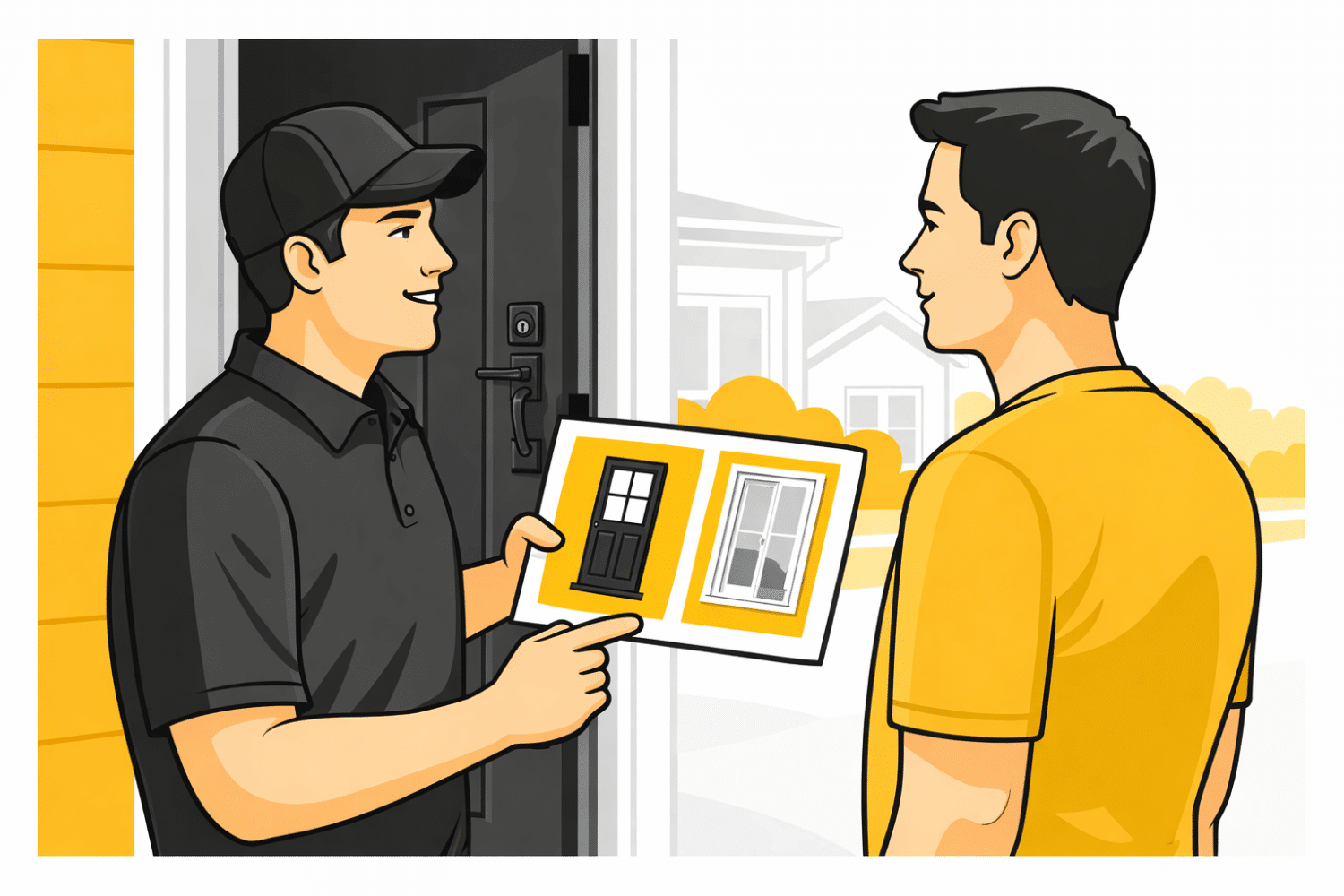

During an in-home consultation, CoMo Premium Exteriors can bring sample catalogs and glass options so you can see how different choices affect light and privacy in your actual entry space.

Energy Efficiency and Comfort in Mid-Missouri Weather

Here in Columbia, we deal with humid summers where temperatures regularly hit the 90s, plus winter cold snaps with serious wind chills. Your exterior doors need to handle both extremes without turning your home into an oven or an icebox.

What Makes a Door Energy Efficient

Both full glass and half glass doors can earn ENERGY STAR ratings when they include:

- Double or triple-pane insulated glass

- Low e coatings that reflect heat

- Warm-edge spacers between glass panes

- Properly insulated frames (fiberglass and foam-core steel perform best)

- Quality weatherstripping and threshold seals

Understanding Energy Ratings

You don’t need to become an engineer, but knowing two basic terms helps:

- U-factor: Measures how well the door prevents heat from escaping. Lower numbers mean better insulation for those cold January nights.

- SHGC (Solar Heat Gain Coefficient): Measures how much solar heat comes through. In our climate, you want moderate SHGC—enough to warm the entry in winter without overheating it in summer.

Look for the NFRC label on doors to compare these ratings between products.

Why Glass Size Matters (But Not as Much as You Think)

Full glass doors have more surface area where poor-quality glass would leak energy. That’s why cheap single-pane full glass doors are a terrible choice for Mid-Missouri—you’d feel drafts all winter and watch your heating costs climb. Modern insulated glass with low e coatings solves this problem entirely.

Here’s what most homeowners don’t realize: air leakage at the frame and threshold causes more drafts than the glass itself. This is why professional installation matters so much. At CoMo Premium Exteriors, we inspect existing framing, check for rot or past water intrusion, ensure the opening is square, and use proper sealants and weatherstripping to minimize air infiltration. A perfectly good door installed poorly will still feel drafty.

Security and Safety: Glass Size vs Glass Quality

Many homeowners worry that more glass means less security. That’s understandable—but it’s not quite accurate. Let’s break down what actually keeps your family safe.

Safety Glass Options

Both full and half glass doors can use safety glass that protects against breakage and intrusion:

- Tempered glass: When broken, it crumbles into small pebble-like pieces instead of dangerous shards. This is the standard for most residential doors.

- Laminated glass: Features a plastic interlayer sandwiched between glass sheets. Even when cracked, the glass holds together, which can slow down forced entry attempts.

- Impact-resistant glass: Designed to withstand hail, debris, and significant force—worth considering for storm doors or lake properties.

Hardware Matters More Than Glass Height

A half glass door with a cheap lock isn’t more secure than a full glass door with a quality deadbolt and reinforced strike plate. Focus on:

- Quality deadbolts with at least a 1-inch throw

- Reinforced door frames and strike plates

- Smart lock options for keyless entry and remote monitoring

- Multi-point locking systems for sliding patio doors

Visibility and Sightlines

Here’s an interesting trade-off: full glass actually makes it easier to see who’s at your door before you open it. You can identify visitors, delivery drivers, or strangers from inside. Half glass may give only a partial view, which is why pairing it with sidelights or a peephole makes sense.

For homeowners with security concerns—especially those with secluded entries or lake properties that sit vacant in the off-season—CoMo Premium Exteriors can recommend specific glass and hardware upgrades to fit your situation.

Best Uses: Where Full Glass and Half Glass Doors Work Well

Rather than thinking about full vs half glass as “better or worse,” consider where each type makes the most sense around your Mid-Missouri home.

Where Full Glass Doors Shine

- Patio and deck doors: The classic application—connect your living area to outdoor space with maximum visibility.

- Walkout basements: Bring light into lower levels that would otherwise feel like caves.

- Lake-facing walls: At Lake of the Ozarks properties, full glass showcases the water views you bought the place for.

- Side entries needing light: When a side door opens into a dark hallway or mudroom, full glass can transform the space.

- Modern new builds: Contemporary homes designed with open floor plans and large windows.

- Remodeled 1970s–1980s homes: Updated exteriors that have traded closed-off layouts for lighter, more open designs.

- Entries set back from the street: When your front door is far from the sidewalk, privacy concerns diminish.

Where Half Glass Doors Excel

- Traditional brick homes in Columbia subdivisions: Matches the architectural style that dominates neighborhoods built in the 1990s–2010s.

- Older central Columbia homes with front porches: Complements historic or traditional character.

- Farmhouses across rural Boone and Callaway Counties: Provides the right balance of style and privacy for country properties.

- Side and back doors: When you want some light but need to keep mudrooms, laundry rooms, or secondary entries more private.

- Homes on busy streets: Where passersby can easily see your front door.

During a free estimate, CoMo Premium Exteriors can walk around your home with you, examine each opening, and recommend full or half glass options based on sun exposure, shade, and how you actually use each door day-to-day.

Cost, Maintenance, and Long-Term Value

Let’s set realistic expectations about what you’ll spend, what upkeep looks like, and how new exterior doors can affect your home’s value and comfort.

What Drives Door Costs

The price difference between full and half glass doors is smaller than you might expect. Cost depends more on:

|

Factor |

Impact on Price |

|---|---|

|

Material (fiberglass, steel, wood) |

Major |

|

Glass package (single vs. double vs. triple pane) |

Major |

|

Hardware quality and finish |

Moderate |

|

Brand and warranty |

Moderate |

|

Custom designs vs. standard sizes |

Significant |

|

Built-in blinds or decorative elements |

Moderate |

Full glass doors may cost slightly more when using larger insulated glass units or integrated blinds. But decorative half glass with intricate patterns or custom grids can carry a premium too.

Maintenance Expectations

- Glass cleaning: Both door types need routine cleaning to look their best. Full glass shows smudges, pet nose prints, and water spots more noticeably.

- Frame and weatherstripping: Check annually for wear, especially after harsh winters. Weatherstripping is easy to replace before drafts become a problem.

- Finish upkeep: Wood doors require periodic refinishing. Fiberglass and steel doors with factory-applied finishes need less attention but benefit from occasional cleaning.

- Hardware: Lubricate locks and hinges yearly to keep everything operating smoothly.

Durability in Our Climate

Fiberglass and steel full or half glass doors generally hold up better than wood in Mid-Missouri’s humidity and temperature swings. Wood can be beautiful but requires more maintenance to prevent warping, swelling, and finish degradation. High-quality factory finishes and proper installation help all door types last longer and perform better.

Value and Curb Appeal

Well-chosen entry and patio doors can significantly improve your home’s curb appeal, energy efficiency, and daily comfort. This makes door replacement a worthwhile exterior remodeling investment. Buyers in Columbia, Jefferson City, and Lake communities appreciate updated doors—especially when they’re energy efficient and fit the home’s overall style.

How CoMo Premium Exteriors Helps You Decide

Choosing between full glass and half glass doors isn’t just about personal preference—it’s about finding the right fit for your specific home, your lifestyle, and your budget. That’s where having a local Mid-Missouri expert makes a difference.

At CoMo Premium Exteriors, we’ve been helping homeowners across the region with exterior remodeling projects for over 25 years. Door installation is part of our larger expertise in windows, siding, roofing, gutters, and decks—which means we can help you make choices that work together rather than looking pieced together.

Our Process

- Free, no-pressure consultation: We inspect your existing doors, measure openings, and discuss how each door is used—whether it’s your front entry, a patio door to the deck, a garage-to-house door, or a basement walkout.

- Side-by-side option review: We’ll show you full vs half glass, clear vs obscure, internal blinds vs exterior shades, and explain how each affects light, privacy, and your budget.

- Coordinated project planning: If you’re also considering new siding, replacement windows, or deck work, we’ll help you create a cohesive exterior that looks intentional.

- Proper installation: We check framing for rot, ensure openings are square, use quality weatherstripping and sealants, and back our work with warranties.

Areas We Serve

We have locations in Columbia, Jefferson City, Boonville, Moberly, and Lake of the Ozarks. We schedule appointments that work with busy homeowners—because we understand you’re juggling family, work, and everything else.

Ready to explore your options? Call CoMo Premium Exteriors at (573) 424-9008 or request a free estimate online. We’ll help you compare specific full glass and half glass products for your home—with honest guidance focused on long-term solutions, not pressure to buy today.

FAQs

Are full glass doors less secure than half glass doors?

Security depends far more on glass type, frame strength, and lock quality than on how much glass your door contains. Both full and half glass doors can be highly secure when built with tempered or laminated safety glass, reinforced frames, and quality deadbolts. A full glass door with a multi-point lock and laminated glass offers better protection than a half glass door with a cheap knob-lock. When security is a priority, we recommend focusing on hardware upgrades and impact-resistant glass rather than simply choosing less glass.

Will a full glass door make my home too hot in summer?

Not if you choose the right glass package and consider your door’s orientation. Low e coatings reflect solar heat while still allowing light through, and double or triple-pane insulated glass creates a thermal barrier. East and west-facing doors receive the most direct sunlight and benefit most from low-SHGC glass. North and south-facing entries are less affected. Proper installation with quality weatherstripping also prevents warm air infiltration. Modern insulated full glass doors can actually perform better than older solid doors that have worn seals.

Can I switch from a half glass door to a full glass door without changing the opening?

In many cases, yes. Standard door sizes allow for swapping between half and full glass options without major structural changes. However, the threshold height, existing framing condition, and surrounding finishes all need to be checked by a professional. If there’s rot in the frame, water damage, or the opening isn’t square, repairs may be needed before installing any new door. During a free estimate, we’ll measure everything and let you know exactly what’s involved.

What if I want privacy sometimes but light other times?

Several options give you flexible control. Blinds-between-the-glass doors have integrated blinds sealed between the glass panes—you can raise, lower, or tilt them without cleaning issues. Exterior shades or cellular shades mounted inside can be adjusted throughout the day. Privacy glass options like frosted or textured patterns provide consistent obscurity while allowing light through. These solutions work on both full and half glass doors, so you don’t have to sacrifice flexibility regardless of which style you prefer.

How long does a typical door replacement take?

Most single-door replacements are completed in one day by our team at CoMo Premium Exteriors. We arrive, remove the old door, prepare the opening, install the new door with proper shimming and sealing, and clean up before we leave. If we discover rot, water damage, or framing issues during removal, repairs may add time to the project—but we’ll discuss that with you before proceeding. Patio door replacements or projects involving sidelights may take slightly longer, and we’ll give you a realistic timeline during your estimate appointment.