Snow Melt, Refreezing, and Hidden Leaks: How Winter Moisture Gets Into Roof Systems

Snow Melt, Refreezing, and Hidden Leaks: How Winter Moisture Gets Into Roof Systems

Key Takeaways

- Mid-Missouri’s freeze-thaw cycles cause snow to melt during warm days, then refreeze at the colder eaves overnight. This creates ice dams that push water back up under shingles, leading to “mystery” winter leaks that appear without any rain.

- Many winter leaks aren’t caused by faulty roof installations—they stem from ice dam formation, attic condensation, and poor insulation or ventilation that allow hidden moisture into the roof system from below.

- Watch for warning signs between January and March: water stains on ceilings or exterior walls, wet insulation in the attic, large icicles at the eaves, and musty odors in the attic space. Early action prevents expensive structural repairs.

- CoMo Premium Exteriors is Mid-Missouri’s only triple-certified roofing and exterior contractor (GAF Master Elite, Owens Corning Platinum, James Hardie Elite), equipped to inspect, diagnose, and permanently fix winter moisture problems—not just patch interior damage.

- Schedule a free winter roof and attic inspection anywhere in Columbia, Jefferson City, Boonville, Moberly, or Lake of the Ozarks by calling (573) 424-9008.

How Snow Melt and Refreezing Create Hidden Winter Leaks

It’s mid-February in Columbia, and a winter storm just dropped six inches of snow on your roof. Two days later, the sun comes out and temperatures climb into the low 40s. You’re feeling good—the snow is melting, the worst is over. Then that night, the mercury plunges back below freezing.

The next morning, you notice a small brown ring on your living room ceiling. There’s no rain in the forecast. No pipes above that spot. So where’s the water coming from?

This scenario plays out in homes across Mid-Missouri every winter. The culprit isn’t a sudden roof failure or a burst pipe—it’s the melt-refreeze cycle that our region’s variable weather creates.

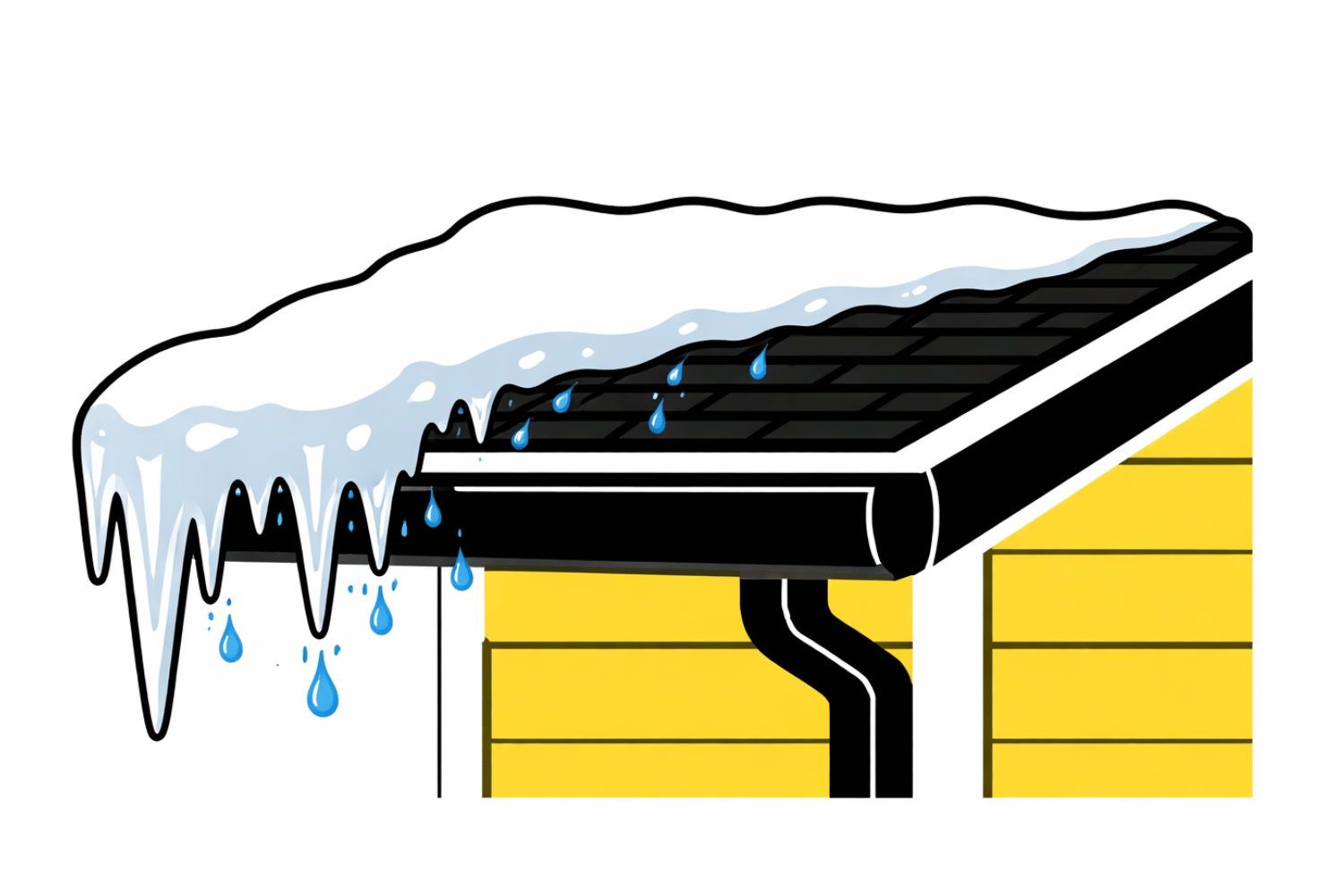

Here’s how it works: During the day, the sun and heat escaping from your attic warm the upper sections of your roof. Snow in these warmer zones begins to melt, and that water flows downhill toward the eaves and gutters. But those lower sections of the roof—especially the overhangs that extend beyond your heated living space—stay colder. When temperatures drop at night, that flowing water refreezes, building a ridge of ice along the roof edge.

This ice ridge, commonly called an ice dam, acts like a small dam on a river. As more snow melts and flows down, it has nowhere to go. Water pools behind the ice barrier and eventually finds its way under shingles, over underlayment, and into nail holes. From there, it can drip into your attic, run along wall cavities, or seep into light fixtures—sometimes showing up as a ceiling stain days after the snow event.

In central and northern Missouri—from Columbia to Moberly to the Lake of the Ozarks—this cycle can repeat dozens of times between December and early March. According to research from the Minnesota Department of Transportation (which shares similar winter patterns with our region), an average of 86 freeze-thaw cycles occur at shallow depths from October to April over a 10-year period. That’s 86 opportunities for water to infiltrate small cracks, expand by approximately 9% when it freezes, and gradually widen those entry points.

Many homeowners first notice issues as small ceiling stains or damp window trim, often assuming a plumbing leak. But when there’s no plumbing above that spot and the weather has been alternating between thaws and freezes, the real culprit is usually snow melt refreezing at the roof edge.

Ice Dams: The Visible Sign of an Invisible Moisture Problem

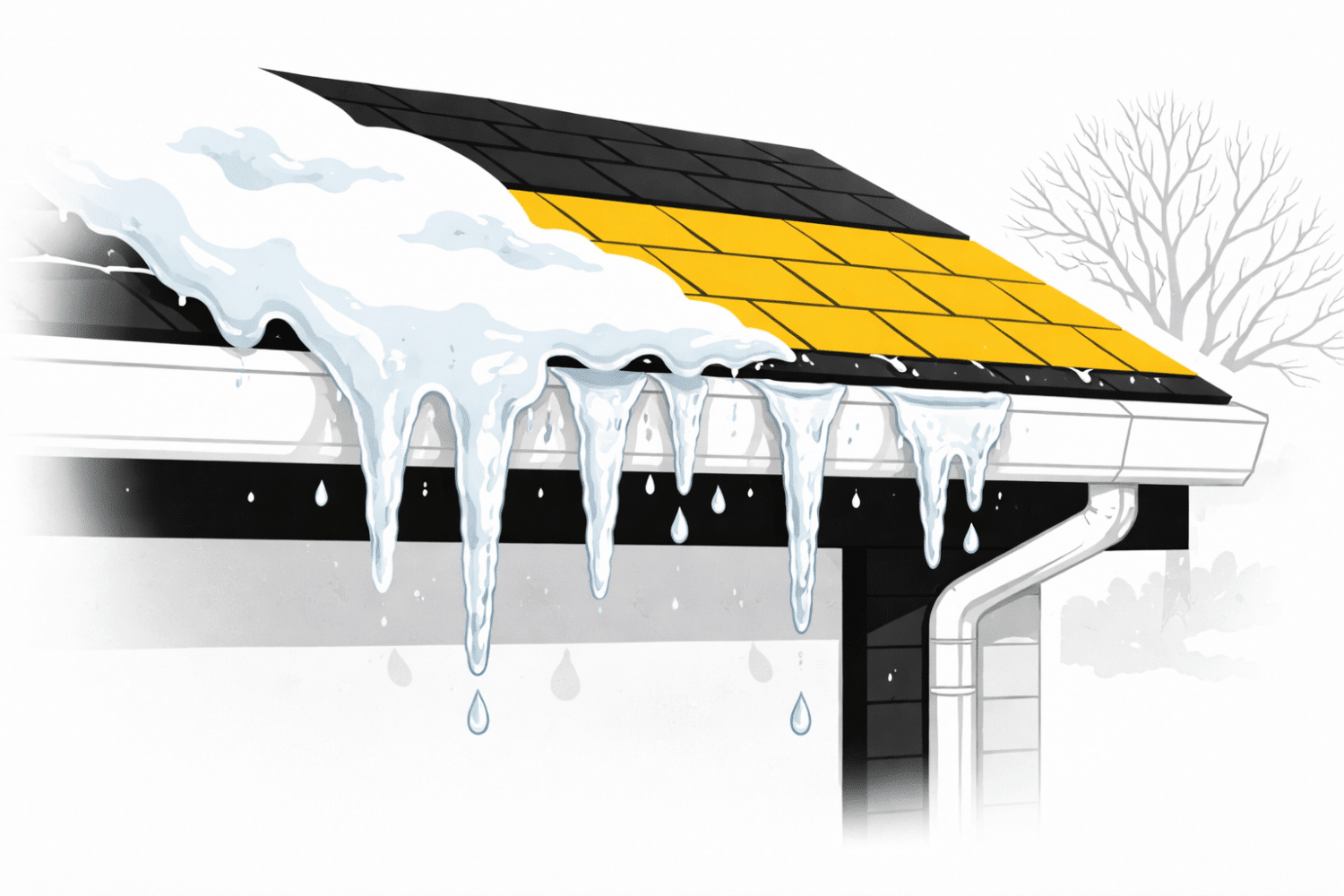

An ice dam is a solid ridge of ice that forms along the eaves and gutters, blocking normal snowmelt from draining off the roof. While the ice itself is visible from the ground, the moisture damage it causes is often hidden inside your roof system for weeks or months.

How Ice Dams Form

Ice dams form when temperatures across your roof surface are uneven. Here’s the typical sequence:

- Heat escaping from your attic warms the upper portion of the roof above 32°F

- Snow on this warmer section begins to melt, even when outdoor temperatures are below freezing

- The meltwater flows down toward the eaves, which are colder because they extend beyond the heated living space

- At the cold eaves, the water refreezes, building up a layer of ice

- As more melt flows down and refreezes, the ice dam grows thicker

- Eventually, liquid water pools behind the dam with nowhere to drain

The University of Minnesota Extension explains that for ice dams to develop, sustained average temperatures must keep lower roof areas below freezing while upper areas thaw snow. The dam essentially self-limits to these cold zones—but it traps water that exploits every crack in your roof’s exterior covering.

Visible Signs of Ice Dam Problems

|

What to Look For |

Where to Check |

What It Indicates |

|---|---|---|

|

Thick icicles hanging from gutters |

Roof edges, especially north-facing |

Active ice dam with melt-refreeze occurring |

|

Solid band of ice at roof edge |

Along eaves above exterior walls |

Significant blockage of normal drainage |

|

Ice-filled or sagging gutters |

All gutter runs |

Debris may be trapping water; drainage compromised |

|

Ice in roof valleys |

Where two roof slopes meet |

Vulnerable area for water backup |

These signs are especially common on north-facing roof slopes in Columbia and Jefferson City, where the sun provides less warming and ice persists longer.

Hidden Effects You Can’t See from the Ground

The real damage from ice dams happens out of sight:

- Water backing up beneath shingles saturates the roof deck

- Wet insulation loses its effectiveness and can take weeks to dry

- Moisture seeps into exterior wall cavities

- Weeks later, you may notice bubbling paint, cracked drywall, or mold growth

Here’s an important point many homeowners miss: a good-quality, correctly installed roof can still experience ice dams if the attic isn’t properly insulated and ventilated. The “roof system” includes the attic, ventilation, and insulation—not just shingles. Addressing only the visible roof surface while ignoring what’s underneath often leads to recurring problems.

Attic Heat, Condensation, and Uneven Roof Temperatures

Ice dams and winter moisture issues almost always tie back to what’s happening under the roof deck—especially in the attic space above living areas and garages. Understanding this connection is key to solving the problem permanently.

How Warm Air Escapes Into Your Attic

Warm interior air from your furnace, showers, and cooking constantly tries to rise and escape through the building envelope. Common escape routes include:

- Gaps around recessed lights (can lights)

- Unsealed attic hatches and pull-down stairs

- Plumbing stacks and electrical penetrations

- Gaps at the top plates where interior walls meet the attic floor

- HVAC ductwork running through unconditioned attic space

When this warm air reaches the attic, it does two things that cause winter moisture problems:

- It melts snow on the upper roof – This creates the temperature differential that leads to ice dam formation

- It carries moist air that condenses on cold surfaces – During January cold snaps, moisture-laden air hitting the cold underside of roof sheathing forms frost or dripping water

This condensation can mimic a roof leak in surprising ways: wet sheathing, dripping nails, damp insulation, and frost buildup that melts on the first warm day. Homeowners often assume their roof is leaking when the moisture is actually coming from inside the house.

Specific Contributors in Mid-Missouri Homes

In our 25+ years serving Central Missouri, we’ve identified common issues in local homes:

- Bathroom fans vented into the attic – Instead of exhausting moist air outdoors, these fans dump humidity directly into the attic space where it freezes and later melts

- Older masonry chimneys – The mass of brick retains heat and warms nearby framing, creating localized hot spots that melt snow unevenly

- Uninsulated knee walls – Common in 1½-story homes, these walls allow significant heat loss into attic areas behind them

- Cathedral ceilings with inadequate air channels – Without proper venting between insulation and roof sheathing, these areas trap heat

Common Indoor Heat Sources That Trigger Winter Moisture Problems

A thorough winter moisture inspection needs to look beyond shingles and flashing. Here are the interior sources we check:

|

Heat/Moisture Source |

How It Affects the Roof System |

|---|---|

|

Recessed (can) lights |

Create hot spots that melt snow directly above; gaps allow warm air into attic |

|

Unsealed attic hatches |

Major air leakage pathway; warm air flows directly into attic space |

|

Leaky HVAC ductwork |

Heats the attic, melts snow above; can also add humidity if connected to humidifier |

|

Whole-house fans |

If not sealed in winter, allow significant heat loss to attic |

|

Bath/kitchen exhaust vents terminating in attic |

Add large amounts of humidity; condensation forms on cold sheathing |

When we perform a winter moisture assessment, checking these penetration points is just as important as examining the roof surface from your driveways or walking the roof itself.

Where Winter Moisture Sneaks In: Typical Leak Paths in Roof Systems

Winter moisture doesn’t always come straight through obvious holes. Water often travels along framing members, nails, and joints, so the leak may show up far from the actual entry point. This is why dripping water in your living room doesn’t necessarily mean the problem is directly above.

Common Vulnerable Areas

Certain locations on any roof are more susceptible to winter moisture infiltration:

- Roof valleys – Where two roof slopes meet, snow accumulates deeper and ice dams form easily

- Chimney surroundings – Counter-flashing and step flashing joints are common failure points

- Skylights – The intersection of glass, frame, and roofing creates multiple potential leak paths

- Plumbing vent boots – Rubber and plastic boots crack in freeze-thaw cycles

- Sidewalls – Where a lower roof meets second-story siding, step flashing must be correctly integrated

- Low-slope sections – Porches, additions, and dormers with shallow pitches hold snow longer

During mid-winter thaws, backed-up snowmelt can push water up under shingles in valleys, around step flashing near second-story walls, and beneath metal counter-flashing at chimneys. The water doesn’t need a large opening—capillary action can draw moisture into surprisingly small gaps.

In homes built before about 2005 in Mid-Missouri, we commonly find limited or no ice-and-water shield membrane at the eaves and valleys. This self-adhering underlayment wasn’t required by code in many areas until more recently, leaving older roofs more vulnerable to wind-driven snow and ice dam backup.

A proper inspection by our team includes not only the top side of the roof, but also attic-side evidence: darkened sheathing, rusty nail heads, wet insulation, and staining around penetration points. Sometimes the attic tells us more about moisture problems than the shingles do.

How Hidden Leaks Show Up Inside the Home

Interior warning signs often appear in January and February, though they may not be recognized as roof-related problems at first:

Common indicators:

- Faint yellow-brown rings on ceilings

- Sagging or cracked drywall at exterior corners

- Swollen or warped window trim

- Peeling paint near outside walls

- Bubbling wallpaper

Less obvious signs:

- Musty smell in the attic

- Higher-than-normal winter humidity on main floors

- Frost on exposed nail tips in the attic

- Ice forming on the underside of roof sheathing during extreme cold

Moisture can flow along the back of drywall or run down top plates, so the visible stain may be several feet away from where water entered the roof system. This makes diagnosis tricky without an attic inspection.

We recommend that homeowners in Columbia, Jefferson City, and surrounding areas do a quick attic check with a flashlight after major snowstorms followed by a warm-up. Look for dark spots on sheathing, damp insulation, or frost patterns—these are early warnings that moisture is getting where it shouldn’t be.

Long-Term Damage from Winter Roof Moisture (and Why Speed Matters)

One ice dam event or condensation episode may seem minor—a small stain, a little dampness. But repeated winter moisture can create serious long-term issues inside the roof system that become expensive to repair.

Structural Risks

When roof decking and framing stay wet through multiple freeze-thaw cycles, deterioration begins:

- Rotting roof decking – Plywood and OSB sheathing absorb moisture and eventually delaminate or rot

- Soft or spongy spots – Walking on the roof reveals areas where decking has weakened

- Weakened rafters or trusses – Chronic dampness leads to wood decay in structural members

- Corroded fasteners – Nails and screws rust, losing their holding power

Interior Risks

The damage doesn’t stop at the roof structure:

- Mold growth – In attic insulation and wall cavities, mold can develop within 24-48 hours of sustained moisture. Studies suggest 60-70% of untreated attic leaks develop mold within months.

- Deteriorating drywall – Repeated wetting weakens drywall, leading to sagging ceilings and crumbling walls

- Ruined insulation – Wet insulation compresses and loses R-value, reducing energy efficiency

- Increased heating costs – Damaged insulation means your furnace works harder, and you’ll see this reflected in higher energy costs throughout winter

Health Implications

Chronic attic moisture creates health risks for your household:

- Mold and mildew can aggravate allergies and respiratory conditions

- Spores spread through HVAC systems into living spaces

- Winter homes with limited fresh air exchange concentrate these contaminants

- Children, elderly residents, and those with asthma face heightened risk

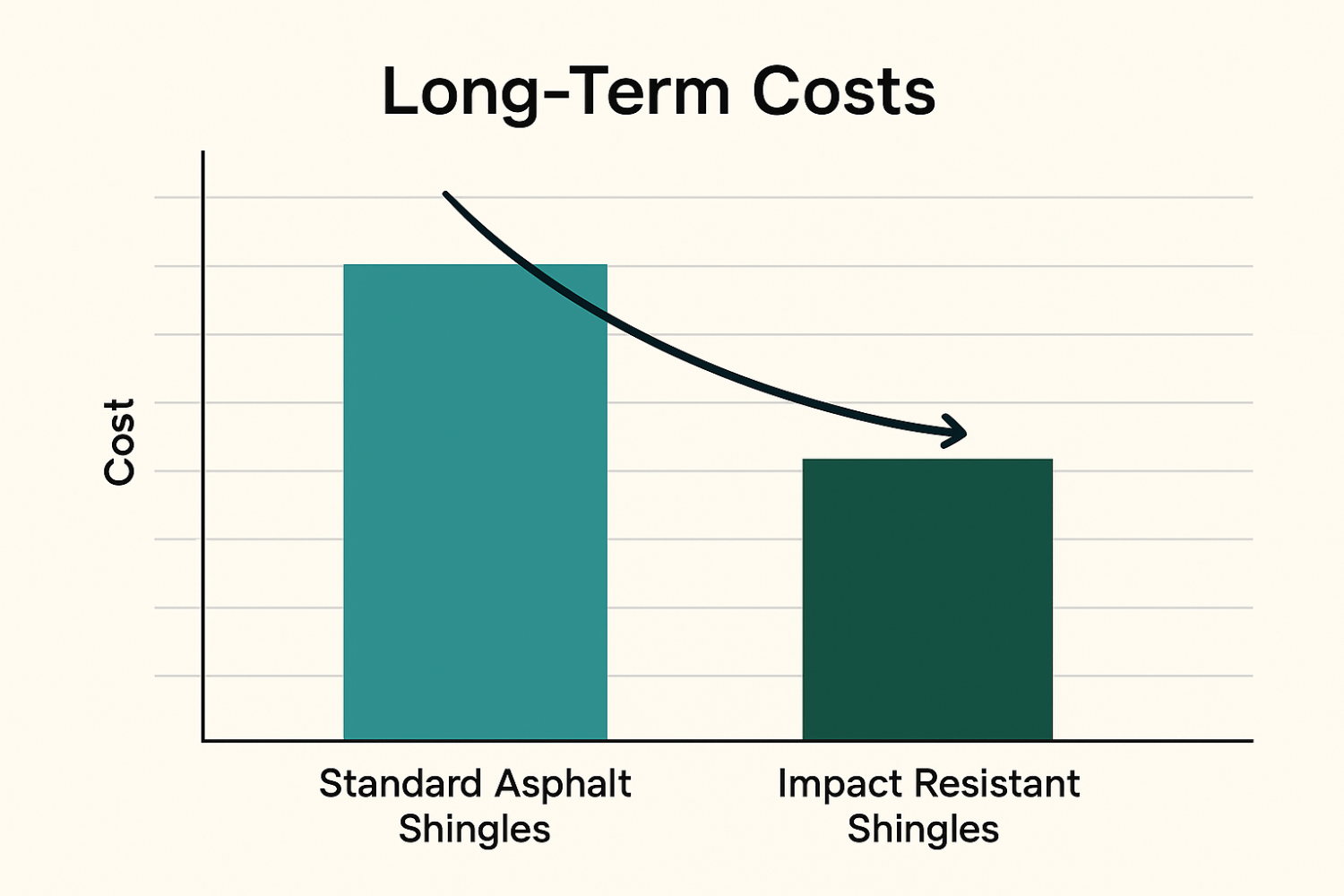

Cost Implications

Here’s the financial reality: repairing minor insulation and flashing issues after the first signs of trouble is far less expensive than replacing sheathing, insulation, and interior finishes after several untreated seasons. What might be a $500-1,500 repair in year one can become a $10,000+ restoration project if moisture damage compounds over three or four winters.

How Winter Moisture Shortens Roof Lifespan

Repeated wetting and refreezing of the roof deck accelerates aging in several ways:

- Sheathing warps, causing shingles to lose proper contact and adhesion

- Freeze-thaw cycles loosen shingle fasteners

- Ice pressing against materials creates new gaps and entry points

- Granule loss accelerates on repeatedly frozen shingles

A well-installed roof with good attic ventilation and insulation can last 25-30 years in Mid-Missouri’s climate. A similar roof plagued by chronic moisture issues may show major problems in just 10-15 years.

An important note on warranties: Manufacturer warranties from GAF, Owens Corning, and other major brands assume proper ventilation and underlayment installation. Chronic ice damming and poor attic conditions can compromise warranty coverage, leaving homeowners responsible for repairs that might otherwise be covered.

Preventing Ice Dams, Condensation, and Winter Leaks in Mid-Missouri

Effective winter moisture control isn’t about any single fix—it’s about the whole system working together: roof covering, underlayment, ventilation, insulation, and air sealing.

Short-Term Emergency Measures

When you’re dealing with an active ice dam or leak, here are immediate steps:

- Remove snow from the roof edge – A roof rake (used from the ground) can clear the lower 3-4 feet of roof, reducing melt feeding the ice dam

- Create drainage channels – In severe cases, professionals can carefully melt channels through ice dams to allow trapped water to escape

- Control interior moisture sources – Run bathroom fans longer, reduce humidifier settings, and ensure dryer vents are clear

However, these are emergency measures, not long-term fixes. Roof raking every storm isn’t sustainable, and aggressive ice removal risks damaging shingles and gutters.

Long-Term Solutions

Based on hundreds of winter moisture cases across Mid-Missouri, here’s what we commonly recommend:

- Upgrade attic insulation – Bringing insulation to R-49 (the current Mid-Missouri code minimum for attics) significantly reduces heat loss through the ceiling

- Improve attic ventilation – Balanced intake and exhaust ventilation keeps attic temperatures closer to outdoor conditions

- Air-seal ceiling penetrations – Sealing gaps around lights, plumbing, and wiring stops warm air leakage at the source

- Install ice-and-water shield during reroofing – This self-adhering membrane at eaves, valleys, and penetrations provides a waterproof backup

Solutions should be tailored to each home’s design. Ranch homes in Columbia behave differently than two-story homes in Jefferson City, and lake homes with complex roofs at Lake of the Ozarks present their own challenges. There’s no one-size-fits-all approach.

The good news: properly addressing winter moisture issues often improves comfort and reduces energy costs year-round, not just during snow season.

Ventilation and Insulation Best Practices for Our Climate

A balanced attic ventilation system works by creating airflow from intake to exhaust:

- Intake vents at the soffits or eaves allow cool outside air to enter

- Exhaust vents at the ridge or high on the roof let warm air escape

- This circulation keeps attic temperatures more uniform, reducing the temperature differential that causes ice dams

For central Missouri homes, we typically follow current building code ratios for net free ventilation area—though many older homes fall short of these standards. The concept is straightforward: prevent your attic from becoming significantly warmer than the outdoors during winter.

Good attic insulation should:

- Provide even coverage across the entire attic floor

- Maintain proper depth (not compressed or settled)

- Include baffles at the eaves to protect soffit vents from being blocked

- Remain dry and fluffy, not wet or compacted

If insulation is damaged, wet, or missing in areas, it needs to be corrected before other improvements will be fully effective.

A word of caution: We don’t recommend DIY-ing major ventilation changes in winter. Cutting new vents in freezing weather creates its own risks, and improper vent placement can actually worsen moisture problems. Schedule an assessment with a certified roofing contractor who understands both manufacturer specifications and local conditions.

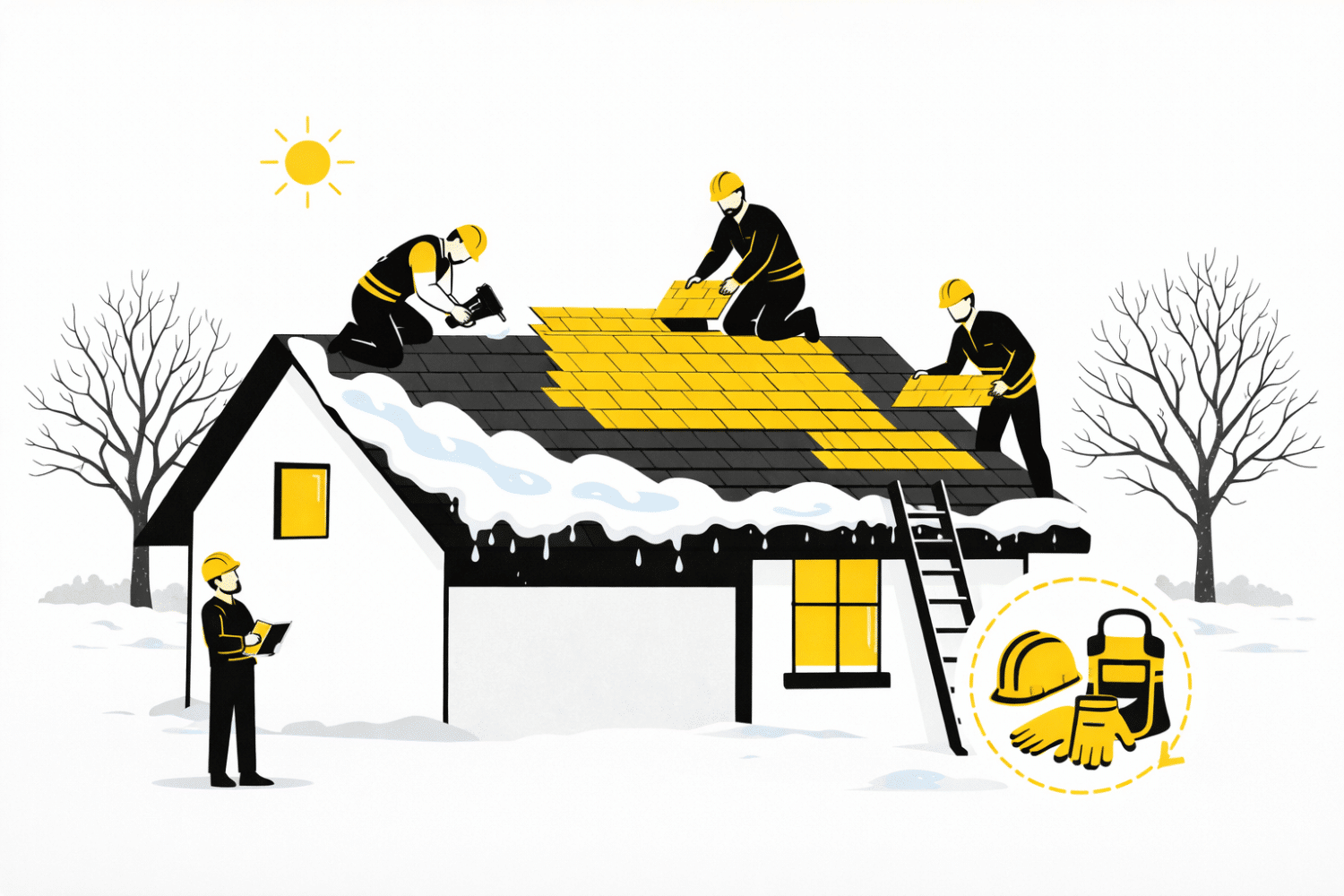

Roofing Upgrades That Protect Against Winter Moisture

When we install or replace a roof, specific components help limit winter leaks:

- Ice-and-water shield membranes – Self-adhering waterproof layer at eaves, valleys, and around penetrations

- High-quality synthetic underlayment – Better water resistance and durability than traditional felt

- Properly flashed chimneys and sidewalls – Correct integration of step flashing, counter-flashing, and kickout diverters

- Correctly sized gutters and downspouts – Adequate capacity to handle snowmelt without backing up

We typically extend ice-and-water protection beyond the minimum code requirements in known trouble spots like low-slope eaves and long valleys. Mid-Missouri’s weather demands this extra margin.

Our triple-certified installation approach (GAF Master Elite, Owens Corning Platinum, James Hardie Elite for siding tie-ins) ensures these details are done to factory standards. This matters for winter performance because manufacturers have engineered their systems to work together—when installation shortcuts happen, winter is often when problems appear.

If your roof was installed before modern underlayment and flashing practices became standard in the 2000s-2010s, a proactive evaluation may prevent potential water damage before it starts.

How CoMo Premium Exteriors Diagnoses and Fixes Winter Roof Moisture Issues

As a local Mid-Missouri contractor, we’ve seen hundreds of winter leak scenarios across Columbia, Jefferson City, Boonville, Moberly, and the Lake of the Ozarks. After 25+ years, patterns repeat—and that experience helps us quickly identify what’s actually going on with your roof system.

Our Inspection Process

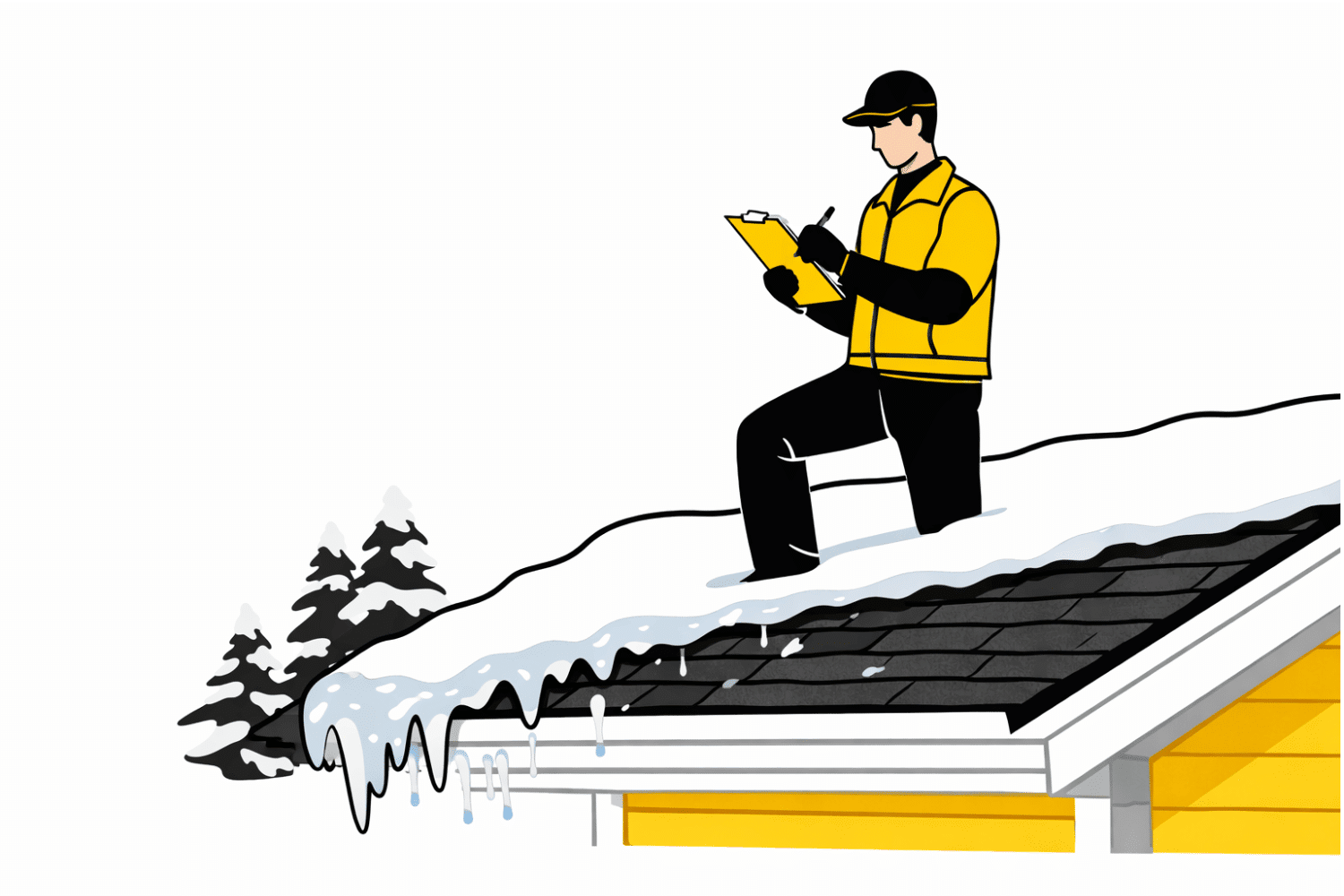

When you contact us about a winter moisture concern, here’s what to expect:

- Exterior roof assessment – When conditions allow safe access, we inspect the roof surface for missing shingles, damaged flashing, ice dam evidence, and vulnerable areas

- Attic inspection – We check for moisture evidence, frost patterns, ventilation adequacy, insulation levels, and air leakage points

- Documentation – We photograph conditions and explain what we’re seeing in plain English

- Diagnosis – We differentiate between true roof failures (missing shingles, failed flashing) and building-science issues (heat loss, condensation)

This last point is critical. Sometimes the solution is a flashing repair. Sometimes it’s adding insulation and sealing air leaks. And sometimes it’s both. We want you to invest money where it actually solves the problem, not just where it’s most visible.

Creating a Prioritized Plan

Based on our findings, we develop a plan that addresses:

- Immediate leak control – If water is actively entering your home, we prioritize stopping it

- Short-term stabilization – Temporary measures to maintain safe conditions through the rest of winter

- Long-term fixes – Air sealing, ventilation upgrades, insulation improvements, and targeted roof repairs or full replacement if necessary

We also offer free estimates and can coordinate with insurance when winter moisture stems from storm-related damage. We help homeowners understand what is and isn’t typically covered, and we’re experienced in documenting damage for adjusters.

When to Call Us (and What to Expect)

Contact CoMo Premium Exteriors if you notice:

- A new ceiling stain appearing after snow, especially without rain

- Recurring winter leaks in the same area year after year

- Heavy icicles and thick ice bands at the roof edge

- Visible frost, dripping, or moisture in the attic

What happens after you call:

- We schedule an on-site assessment at a time that works for you

- We perform a thorough inspection of roof, attic, and relevant interior areas

- We explain our findings in clear, straightforward language

- We provide a written estimate with options (repair vs. long-term solution)

There’s no high-pressure sales pitch. Our goal is to educate you and let you decide when and how to move forward. Many of our customers appreciate having the information even if they’re not ready to act immediately.

Ready to get answers? Call us at (573) 424-9008 or request an inspection through our website. With more freeze-thaw cycles ahead this winter, acting before the next major snow or temperature swing helps prevent the situation from getting worse.

FAQs

Can an ice dam damage my roof even if I don’t see water inside the house?

Yes. Ice dams can soak roof decking and insulation without immediately causing interior stains. The moisture may saturate sheathing and insulation for weeks before it eventually shows up as sagging drywall, a musty attic odor, or mold on stored items.

If you see heavy icicles or thick ice at the eaves during January or February, we recommend scheduling a roof and attic inspection even if there’s no active leak yet. Early inspections often let us identify and fix minor issues—like localized underlayment or flashing problems—before they lead to major repairs.

Is it safe to remove ice dams myself with a shovel, hammer, or roof rake?

Using a roof rake from the ground to remove fresh snow is generally safe when done carefully. However, aggressive chipping at ice with hammers, shovels, or picks can easily break shingles, dent gutters, and damage fasteners—creating new leak points that show up during spring rains.

For severe ice dams, professional steam-based removal is safer than mechanical methods. But the real answer is prevention: proper insulation, ventilation, and air sealing address the root cause so you’re not managing an emergency situation every winter.

Will my homeowners insurance cover damage from ice dams or winter roof leaks?

Many policies in Missouri cover resulting interior water damage from sudden ice dam events—things like stained ceilings, damaged drywall, and ruined flooring. However, policies typically don’t cover the underlying cause, such as inadequate attic insulation, poor ventilation, or pre-existing roof wear.

Coverage varies significantly by policy and carrier. We recommend reviewing your policy or talking with your agent to confirm specifics. When appropriate, CoMo Premium Exteriors assists homeowners in documenting winter damage and communicating with adjusters so they understand what repairs are needed. We can help you file a claim correctly when winter damage qualifies.

When is the best time of year to fix winter moisture problems with my roof and attic?

We can perform emergency leak-control work any time, including during winter weather. However, major fixes—like full roof replacements, extensive ventilation modifications, or large insulation projects—are typically best scheduled for spring through fall when weather conditions allow for proper installation.

The key is to call as soon as you notice an issue. We can stabilize the situation, prevent further damage, and plan permanent solutions for the next available weather window. Waiting multiple seasons often compounds the damage, increasing both repair cost and disruption to your household.

How do I know if I need a full roof replacement or just targeted repairs and attic improvements?

The answer depends on several factors: the age of your roof, visible wear patterns (curling shingles, significant missing granules, exposed fasteners), and how widespread the moisture damage is to decking and underlayment.

We evaluate both the roof surface and the attic to determine whether strategic repairs plus insulation and ventilation improvements will solve the problem, or whether a full replacement is the more cost-effective long-term option. Sometimes a 15-year-old roof with localized ice dam damage needs only flashing work and attic upgrades. Other times, widespread sheathing damage makes replacement the smarter investment.

We share photos and clear explanations so you can see exactly what we see before making any decision. Our role is to give you the information—not to pressure you into a particular choice.