Choosing the Right Membrane Roof: Your Essential Guide to Durable, Low-Slope Roofing

Flat and low-slope roofs require specialized roofing systems to protect against water damage, which is where membrane roof systems come into play. These membrane roofs not only offer durability and ease of maintenance but also come in various types to suit different needs. In this blog post, we’ll explore the world of membrane roofs in detail, covering everything from their purpose and types to essential factors to consider and maintenance tips.

Key Takeaways

- Understanding membrane roofs requires knowledge of materials, installation methods and longevity for long-term protection.

- Membrane roofing systems provide durability, minimal maintenance & strong seams making them a reliable solution for low slope roofs.

- Common challenges such as leaks, blistering and shrinkage can be addressed with various solutions including environmentally friendly options to reduce one’s carbon footprint.

Understanding Membrane Roofs: What You Need to Know

Illustration of a flat roof with membrane roofing

Membrane roofs, a type of flat roof materials, are designed to safeguard the interior of buildings with flat or low-slope roofs from water damage. These roofing systems employ flat roof membranes, which utilize materials such as:

- Thermoplastic

- Synthetic rubber

- Modified bitumen

- Liquid polyurethane A well-installed roof membrane ensures long-lasting protection and durability for your building.

To create a watertight barrier, PVC roofs polyvinyl chloride are one of the popular options for membrane roofing.

Modified bitumen systems, thermoset membranes, and thermoplastic membranes are the three primary types of roof membranes. Each material offers distinct advantages for installation, lifespan, and usability. The installation methods for roof membranes include adhesive or heat, such as in torch-down roofing, which is an alternative to tar and gravel roofs. When properly installed and maintained, membrane roofs can last up to 30 years, making them a durable alternative to traditional gravel roofs.

The Benefits of Membrane Roofing Systems

Membrane roofing systems offer numerous advantages compared to traditional roofing systems, such as built-up roofs. These benefits include:

- Durability

- Minimal maintenance

- Energy efficiency

- Stronger seams or seamless design, reducing the possibility of leaks

- Easier identification of leaks, simplifying the repair process

A Self-Adhering Membrane Residential Roof System is particularly well-suited for low-slope roofs that may be subject to foot traffic, as it provides long-term protection against snow, ice, and other elements. EPDM (ethylene propylene diene monomer) is a cost-effective, fire-resistant material for membrane roofs that can provide a long-term service life of up to 20 years with correct installation and maintenance.

Types of Membrane Roofs: A Comprehensive Overview

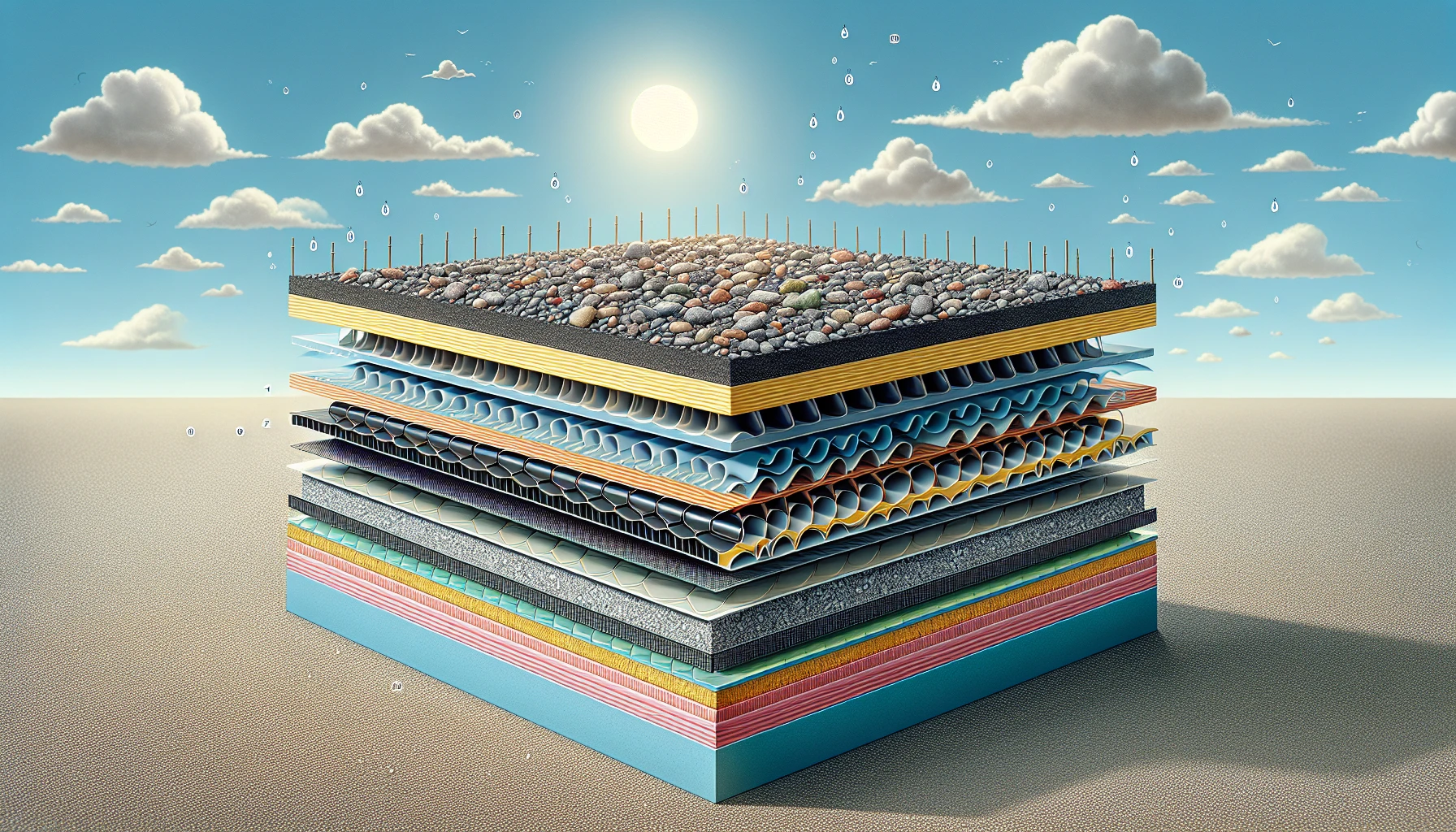

Illustration of built-up roof membrane layers

This part of the guide covers the three primary kinds of membrane roofing systems: built-up roof membranes (BUR), modified bitumen roof membranes, and single-ply membranes. Each type has its distinct advantages and applications, and understanding the differences between them can help you choose the most appropriate roofing system for your needs.

Built-Up Roof Membranes (BUR)

Built-Up Roof Membranes (BUR) are composed of layers of bitumen and reinforcing fabric sheets arranged in an alternating pattern. BUR systems have a long history of successful use, providing a reliable track record. Known for their durability and longevity, BUR systems are applied in layers, creating a robust and waterproof surface.

However, one of the drawbacks of BUR systems is their weaker seams compared to newer membrane systems, which can make sealing more difficult. Additionally, maintenance and repair work for built-up roofs can be more complex than for other membrane roof types.

Modified Bitumen Roof Membranes

Photo of modified bitumen roof installation

Modified bitumen roof membranes, like built-up roof membranes, are designed with enhanced elasticity and strength, making them more resistant to damage and leaks. These membranes are composed of one or more premanufactured sheets of asphalt and reinforced layers. Installation methods for modified bitumen roofing include:

- Hot-mopped asphalt

- Cold adhesive

- Hot-mopping

- Self-adhering materials

While modified bitumen roofing offers increased durability through multiple layers and proven weatherproofing materials, it does require regular maintenance and may be susceptible to damage due to extreme temperatures.

Single-Ply Membranes

Single-ply membrane roofing systems consist of a single layer of synthetic material that forms a waterproof seal. These systems can be classified into two main categories: thermoset membranes, which are made from ethylene and propylene materials (such as EPDM), and thermoplastic membranes, which soften upon exposure to heat (such as PVC and TPO).

The advantages of single-ply membranes include:

- Durability

- Chemical resistance

- Fire resistance

- Water resistance

- Wind resistance

These qualities make them a popular choice for many roofing applications. To prevent problems such as shrinkage, tears, and punctures, it’s necessary to select a top-grade membrane and guarantee correct installation.

Factors to Consider When Choosing a Membrane Roof

Illustration of factors influencing membrane roof selection

Choosing a membrane roofing system requires considering aspects like climate, budget, and roof slope. For instance, in winter weather conditions, membrane roofs may be at risk of damage if not properly maintained. Given the extreme weather conditions due to climate change, it’s necessary to choose a membrane roof that can endure varying temperatures.

The budget for various types of membrane roofs can vary depending on the material used, the size of the roof, and the complexity of the installation. To get a better understanding of membrane roofing cost, it is advisable to consult with roofing professionals or contractors to obtain precise pricing information for specific membrane roof types.

Also, a Self-Adhering Membrane Residential Roof System is generally suitable for roofs with a minimum slope of 1:12.

Membrane Roof Installation Methods

There are different installation methods for membrane roofing systems, including:

- Heat welding: This involves fusing two PVC or TPO sheets together using hot air welding, creating a single, permanent seal between the membranes and providing a watertight and durable roof surface.

- Adhesive bonding: This method uses adhesive to bond the membrane to the roof substrate, creating a strong and secure attachment.

- Mechanical fastening: This method involves using screws or other mechanical fasteners to secure the membrane to the roof substrate, providing a reliable and long-lasting installation.

Adhesive bonding, on the other hand, involves using roofing adhesives to firmly bond the membrane to the roof substrate. This method guarantees that the membrane is correctly adhered to the roof, preventing water infiltration and improving the overall performance of the roof system.

Proper Maintenance for Long-Lasting Membrane Roofs

Photo of membrane roof maintenance inspection

Consistent inspection and maintenance can prolong the life expectancy of a flat roof. Recommended practices for maintaining a membrane roof include:

- Making temporary repairs with lap sealant or construction-grade caulk

- Cleaning the roof surface regularly with a mild household detergent and water

- Removing debris from the roof

- Clearing drains to avoid water accumulation

- Conducting regular inspections of the roof surface, penetrations, and perimeter

While inspecting membrane roofs, one should look for issues like:

- Punctures

- Tears

- Moisture infiltration due to improper storage

- Exposed seams

- Shrinkage

- Flashing failure

- Lap problems

Proper maintenance can help identify and address issues early, preventing more significant damage and prolonging the roof’s lifespan.

Hiring a Professional Roofing Contractor: Why It Matters

Hiring a professional roofing contractor ensures safety and proper installation of your membrane roof. It is important to take into account indicators such as their locality, pressure tactics, insurance coverage, ability to explain the process, business license, communication skills, product quality, and warranty length when selecting a roofing or siding company.

Hiring a professional roofing contractor offers several benefits, including:

- Working with licensed, insured, certified, and experienced installers

- Clear communication throughout the project

- Support for a local, family-run enterprise

These factors ensure that your membrane roof is installed and maintained correctly, leading to a longer lifespan and better overall performance.

Common Membrane Roof Challenges and Solutions

Common challenges faced by membrane roofs include leaks, blistering, shrinkage, and ponding. For leak repair, the steps include cleaning the area, removing any dirt or debris, scrubbing the area beyond the repair boundaries with a cleaner or detergent, wiping the surface clean with acetone, cutting a tape to size for the repair, removing the backing from the tape, and applying it to the damaged area to cover the leak entirely.

Blistering in membrane roofs can be attributed to errors in the manufacturing process, creating voids that trap moisture and air between the layers of the membrane. Preventing membrane roof shrinkage requires correct installation of the membrane, selection of a high-quality membrane, and an efficient roof design.

Various solutions are available for membrane roof ponding, such as:

- Utilizing Spray-Polyurethane Foam (SPF) for full-roof restorations or repairs

- Flushing existing drains and fixing low spots

- Adding more drain lines to improve water drainage.

Environmentally Friendly Membrane Roofing Options

Eco-friendly membrane roofing options include:

- Green roof membranes

- PVC roofing membranes

- FiberTite® roofing systems

- Metal roofs

- Wood shakes and shingles

- Clay and concrete tiles

- Asphalt shingles

Utilizing eco-friendly membrane roofing offers the advantage of reducing one’s carbon footprint through the implementation of sustainable practices.

Environmentally friendly membrane roofing systems can provide a range of benefits, such as extended service life, durability, and recyclability. Materials like EPDM are non-toxic, making them an environmentally safe option. Cost considerations for installing eco-friendly membrane roofing should include aspects like the type of membrane, the roof size, and installation complexity.

Summary

In this blog post, we’ve explored the world of membrane roofs, their importance for flat and low-slope roofs, and the various types available. We’ve discussed the factors to consider when choosing a membrane roofing system, the different installation methods, and the importance of proper maintenance. By understanding the advantages and disadvantages of each type of membrane roof, considering factors such as climate, budget, and roof slope, and hiring a professional roofing contractor, you can ensure the longevity and performance of your membrane roof.

Frequently Asked Questions

What is a membrane for a roof?

Membrane roofing is a popular choice for flat and low-sloped roofs, and often consists of thin, single layers of materials like synthetic rubber, thermoplastic or modified bitumen. It creates a continuous watertight covering to protect the interior of a building from water intrusion and the elements.

Are membrane roofs any good?

Membrane roofing is a high-quality option, especially EPDM which has long life expectancy and is easy to repair. PVC also offers chemical, fire and wind-resistance with hot-air welded seams providing water-resistance. Both materials are suitable for hot climates, making membrane roofs an excellent choice.

What are the disadvantages of membrane roofing?

Membrane roofing can be expensive to install, requires experienced professionals and is generally not suitable for flat roofs. It also tends to be prone to damage from extreme weather conditions and wear-and-tear over time.

What goes under a membrane roof?

Under a membrane roof, a waterproof or water resistant barrier such as underlayment is typically installed directly to the roof deck before the actual roof material is added. This provides protection for the roof deck during the installation process. Materials like synthetic rubber, thermoplastic, liquid polyurethane, and modified bitumen can all be used for the construction of a membrane roof.

What types of roofs are suitable for membrane roofing?

Membrane roofing is ideal for flat and low-sloped roofs with a slope of less than 3:12, making it suitable for residential, commercial, and RV settings.