Imagine it’s raining, and water starts seeping through your home’s walls and ceilings. The culprit? Inadequate roof flashing. To prevent such water damage, it’s essential to understand the importance of roof flashing and how it protects your home. In this blog post, you’ll learn about the essentials of roof flashing, the right material choices, and how CoMo Premium Exteriors ensures proper installation.

Key Takeaways

- Roof flashing is a corrosion-resistant sheet metal used to direct water away from vulnerable areas.

- Careful consideration must be taken when selecting the right material for roof flashing, as each option has its own merits and demerits.

- CoMo Premium Exteriors provides waterproof roofing solutions through their use of high quality materials and attention to detail in installation processes.

The Essentials of Roof Flashing

Illustration of roof flashing

Roof flashing plays a pivotal role in safeguarding your home against water damage. But what exactly is it? Roof flashing is a thin, corrosion-resistant sheet metal designed to fit into joints to help direct water away from vulnerable areas. Its primary purpose is to prevent water damage, such as roof flashing leaks.

Defining Roof Flashing

Roof flashing, a thin sheet of metal, is tactically placed around roof features and penetrations to efficiently guide water away and avoid possible damage. Various types of roof flashing, including drip edge flashing, are commonly utilized, such as:

- Base flashing

- Step flashing

- Counter flashing

- Apron flashing

- Headwall flashing

- Pipe flashing

Metal roofs require roof flashing to be installed. To install roof flashing, this needs to be done on top of the metal panels. The material used for roof flashing is usually constructed of thin sheets of metal, such as aluminum, galvanized steel, or copper.

Importance for Your Roof System

Correct installation of roof flashing is imperative in maintaining the roof system’s integrity and warding off costly repairs. Counter flashing, for instance, is typically laid over step flashing between the roof’s surface and chimney seams, providing an extra layer of protection against water infiltration.

Roof flashing redirects water away from vulnerable areas, thus preventing water damage and extending the lifespan of the roof. By ensuring proper installation and maintenance of your roof’s flashing, you can avoid a roof flashing leak and costly repairs.

Selecting the Right Material for Your Flashing

Photo of different roof flashing materials

Selecting the apt material for your roof flashing is vital for its longevity and performance. Homeowners may select aluminum, steel, or copper for their roof flashing, depending on their budget and desired durability.

Each material has its merits and demerits, so it requires thoughtful consideration of your options before finalizing a choice. In the subsequent paragraphs, the advantages and disadvantages of aluminum, galvanized steel, and copper roof flashing materials will be examined.

Aluminum Flashing

Aluminum flashing is a lightweight and cost-effective material used to safeguard roofs from water damage. Its advantages include:

- Resistance to corrosion

- Availability

- Ease of use

- Cost-effectiveness compared to other materials such as copper or stainless steel.

However, aluminum flashing has certain drawbacks, like diminished durability compared to materials such as copper or stainless steel and potential deficiency in strength and robustness in comparison to other materials. Generally, aluminum roof flashing is expected to last between 15-20 years.

Galvanized Steel

While galvanized steel is a dependable and economical metal flashing type, it ranks lower in durability and can deteriorate over time. The process of galvanizing steel for roofing flashing involves coating the steel with a layer of zinc to provide protection from corrosion and extend its service life.

The life expectancy of galvanized steel flashing on a roof is up to 40 years. However, it is important to bear in mind that galvanized steel can corrode or rust over time, thus necessitating regular maintenance and inspections to ensure its longevity.

Copper Roof Flashing

Copper flashing is a premium choice due to its:

- longevity

- resistance to extreme weather conditions

- durability

- resistance to corrosion

These qualities make it an ideal choice for withstanding harsh weather conditions.

However, copper flashing comes with a higher price tag than other options and forms a green patina over time. Despite the steeper price, copper flashing continues to be a favored choice among homeowners seeking a sturdy and enduring solution.

Installation Insights: How CoMo Premium Exteriors Fits Flashing

CoMo Premium Exteriors is committed to providing waterproof roofing through their flashing techniques. They achieve this by:

- Utilizing proper installation practices

- Using high-quality materials

- Paying attention to detail during the installation process to ensure that the flashing is properly sealed and integrated with the roofing system.

CoMo Premium Exteriors also uses durable and weather-resistant flashing materials to ensure long-lasting protection against water damage. In the subsequent paragraphs, the expert techniques employed by CoMo Premium Exteriors for installing base and step flashing, and counter flashing for improved protection will be discussed.

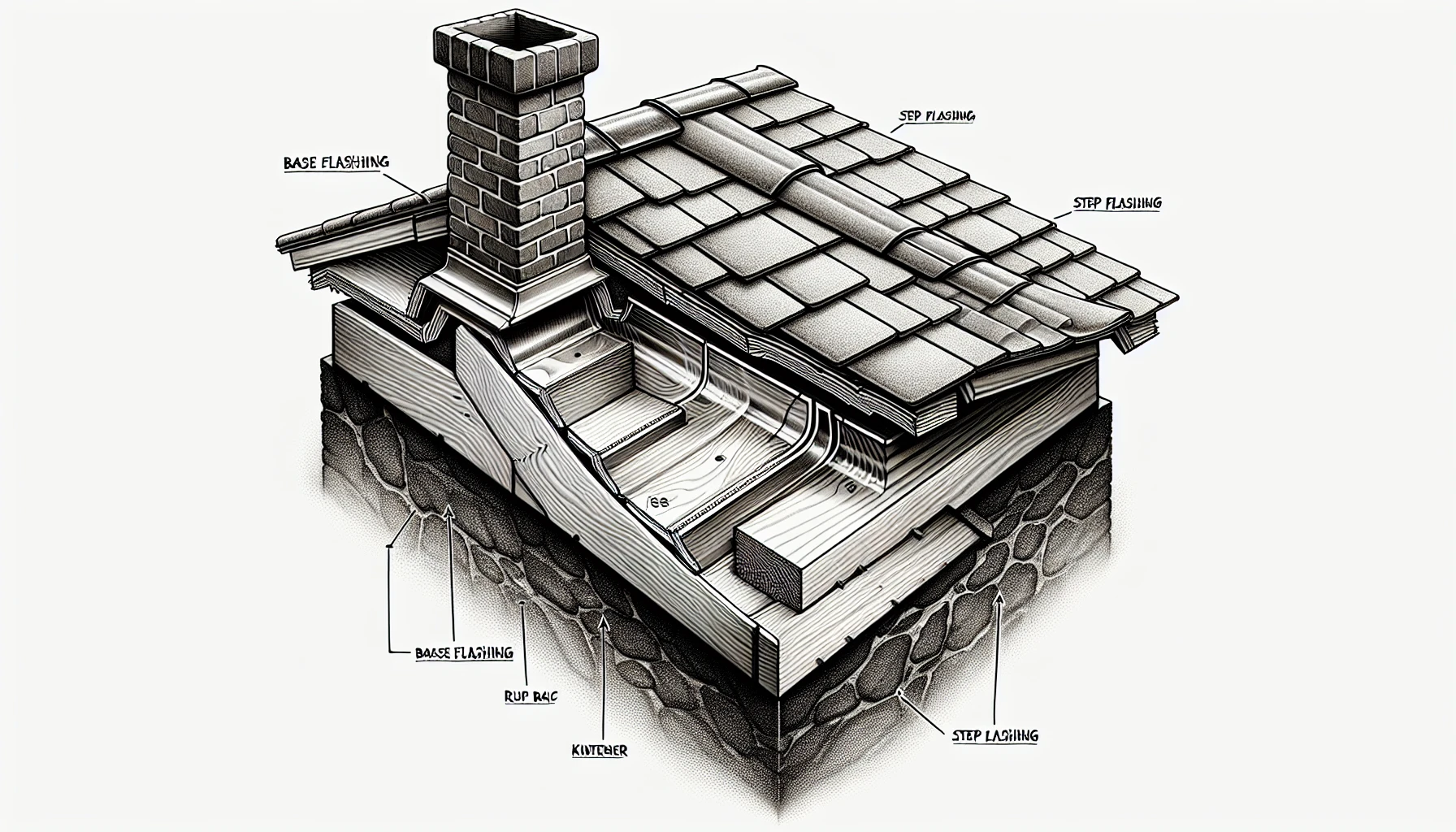

Base and Step Flashing Techniques

Illustration of base and step flashing techniques

Base flashing is a piece of flashing that is installed at the base of roof penetrations, such as chimneys or vents, to direct water away from these critical areas. Additionally, step flashing and wall flashing are utilized to protect the areas where the roof meets a vertical surface, such as a wall or a dormer, by creating a step-like pattern of overlapping flashing pieces to prevent water infiltration.

To guarantee correct installation of base and step flashing, it’s necessary to utilize suitable tools and adhere to a systematic procedure. This helps to create a watertight barrier that stops water from infiltrating vulnerable parts of the roof, thereby averting leaks and water damage to the roof and underlying structure of the building.

Counter Flashing for Enhanced Protection

Counter flashing plays an integral role in roof flashing installation, acting as a protective barrier against water infiltration. To install counter flashing, it is placed on top of the base flashing to help prevent water from passing the flashing and entering the roof.

Counter flashing seals the top of the base flashing, allowing water to flow down the roof and not penetrate the roofing system, thus protecting the roof and underlying structure from water damage. Valley flashing helps to protect the roof valleys from water damage and enhances their overall water resistance.

Recognizing When Flashing Needs Attention

Regular check-ups can help pinpoint when roof flashing requires attention or repair. Visible damage, corrosion, or warping in the flashing material should be noted, and signs of roof leaks, such as water stains or mold growth, may indicate that the flashing needs repair or replacement.

Neglecting flashing issues can result in various problems, including:

- Water leaks

- Water damage

- Decay

- Mold and mildew proliferation

- Structural harm

To prevent these issues, it is recommended that roof flashing be inspected at least biennially, though more frequent inspections may be advised.

Visible Damage and Corrosion

Photo of visible damage and corrosion on roof flashing

Visible harm and corrosion to the roof can adversely affect its overall health by:

- Speeding up deterioration

- Leading to water leaks

- Encouraging mold and mildew growth

- Compromising structural integrity

- Escalating maintenance and repair costs.

Galvanic corrosion is the phenomenon responsible for corrosion on various flashing materials such as Aluminum, Galvanized Steel, or Copper. When dissimilar metals come into contact with each other and are exposed to an electrolyte like water, corrosion can occur. To avoid corrosion, it is essential to utilize compatible metals and perform regular maintenance and inspections.

Signs of Roof Leaks

Signs of roof leaks caused by faulty flashing include:

- Shingles being raised around the flashing

- Water stains on walls and ceilings

- Discoloration on the ceiling or walls

- Leaks during rainfall

- Mold on exterior walls

- Damage to the flashing

To spot roof leaks in the attic, one can:

- Inspect the underside of the roofing for water stains or damp areas

- Use a handheld or drone infrared camera to find water in the roof or attic

- Scrutinize the sheathing in the attic for any damp spots or visible droplets

If you suspect a roof leak, it’s essential to address the issue promptly to prevent further damage to your roof deck.

CoMo Premium Exteriors’ Commitment to Quality Flashing

CoMo Premium Exteriors is a top-rated roofing company that serves Missouri, offering various services, including roof flashing installation and repair. Their dedication to quality flashing is based on the utilization of high-grade materials, skilled workmanship, painstaking attention to detail, and custom-made options.

As a trusted local roofing contractor, CoMo Premium Exteriors is BBB Accredited in Columbia, Missouri, and provides free exterior remodeling estimates and free roofing inspections to ensure the best quality flashing for your home.

Our Warranties and Guarantees

CoMo Premium Exteriors provides a 5-year workmanship warranty, a 1-year clean-up assurance, and honors the manufacturer’s warranty for all materials used. This means that they stand by their work and the quality of the materials they use, ensuring that your roof flashing is properly installed and maintained.

The 5-year workmanship warranty covers:

- Leaks resulting from improper installation of flashing

- Issues related to flashing such as poor installation or defects

- Other installation-related defects associated with flashing

The 1-year clean-up guarantee guarantees that any debris or mess generated during the exterior renovation or construction process will be cleared up within one year of the project’s conclusion.

Professional Installation Standards

CoMo Premium Exteriors adheres to professional installation norms to ascertain that your roof flashing and roof decking are correctly installed with the aim of protecting your home from water damage. They adhere to the criteria set by leading shingle manufacturers such as GAF and Owens Corning, thus aligning with industry standards.

Their roofing professional typically adheres to standard procedures for flashing installation, such as:

- Understanding safety standards and adhering to building codes

- Removing any existing flashing on the roof

- Installing new flashing made of aluminum or galvanized steel

- Ensuring quality installation and maintenance for the long-term integrity of the roofing system.

Summary

In summary, roof flashing is a critical component in protecting your home from water damage. By understanding the essentials of roof flashing, selecting the right material, and trusting a professional like CoMo Premium Exteriors to install and maintain your flashing, you can keep your home safe and dry for years to come.

Frequently Asked Questions

What is a flashing on a roof?

Flashing is a metal material used to direct water away from seams and joints of a roof, helping to keep the roof waterproof. It prevents water from entering openings and cracks in the roofing system.

Do you put flashing before shingles?

Yes, you put flashing before shingles by installing a shingle, then a piece of flashing, then another shingle, then a piece of flashing until the wall is completely protected. The bottom edge of the flashing should extend just below the nail line and each piece of step flashing laps over the shingle below and under the shingle above.

Can I fix roof flashing myself?

Educating yourself about home repair is wise, however roof flashing repairs should be left to the trained professionals for best results.

What does flashing look like?

Flashing on a roof typically appears as thin sheet metal installed against the roof decking, or as stairstep-like metal rectangles along chimneys and dormers.

What is the purpose of roof flashing?

The purpose of roof flashing is to create a waterproof seal and protect the structure from water damage.