Ultimate Guide to Install Vinyl Siding: Step-by-Step Techniques for a Flawless Exterior

Are you ready to transform your home’s exterior with a flawless install vinyl siding project? Vinyl siding is an economical choice, requiring minimal maintenance and offering a beautiful aesthetic. In this comprehensive guide, you’ll learn step-by-step techniques to master the art of install vinyl siding, ensuring a polished and professional look for your home.

Key Takeaways

- Prepare your home for vinyl siding installation by assessing wall conditions and removing old siding and trims.

- Lay the groundwork with starter strips, flashing, cutting techniques with tin snips/utility knife, attaching panels & ensuring proper alignment/overlap.

- Finish off the project by installing soffit & fascia. Trimming windows & doors. Sealing& caulking. Nail placement technique for expansion/contraction control. Custom fitting around obstacles.

Preparing Your Home for Vinyl Siding

A clean workspace for vinyl siding installation

Before we begin the installation process, preparation of your home for vinyl siding is necessary. This includes assessing wall conditions, removing old siding and trims, and setting up a clean workspace. Proper preparation will set the stage for a seamless and successful siding installation.

Assessing Wall Conditions

A smooth, level wall surface is necessary for the accurate installation of vinyl siding. Vinyl siding is a great modern home-siding option that can be easily installed on most wood sheathings such as plywood, OSB, and more. Foam plastic insulating sheathing is one of the materials that it can be installed on. To ensure proper installation, make sure that nails are long enough to penetrate 1 1/4” (32mm) into the framing behind the foam. Moreover, consulting your local building code for the requirements relevant to your geographic area, including the use of stainless steel fasteners, is important.

When assessing wall conditions, inspect for the following:

- Cracks or gaps in the siding

- Warping or buckling

- Deterioration or aging

- Missing or rusty nails

Address any issues accordingly to create a solid foundation for your vinyl siding installation.

Removing Old Siding and Trims

Prior to installing new vinyl siding, removal of the old siding and trims is required. This will ensure a smooth and level surface for the new siding to be installed on. Utilize the following tools to remove the existing siding and trims:

- Hammer

- Snips

- Utility knife

- Flat pry bar

- Cat’s paw

- Siding removal tool (also known as a zip tool)

Be sure to follow safety precautions and inspect for water damage during this process.

After removing the old siding and trims, repairing any damage and applying a water-resistive barrier to prevent incidental water infiltration is imperative. This barrier, combined with proper sheathing and insulation, will create a solid base for your vinyl siding installation.

Setting Up a Clean Workspace

Organizing and keeping a clean workspace is critical for efficiency and safety during the installation process. A level and smooth surface is the most suitable for a vinyl siding installation workspace.

Arrange the siding according to length and width, put on the necessary work clothes, gloves, and masks, and protect the home and workspace during removal. Ensure all tools and materials are within reach and free from clutter or obstructions.

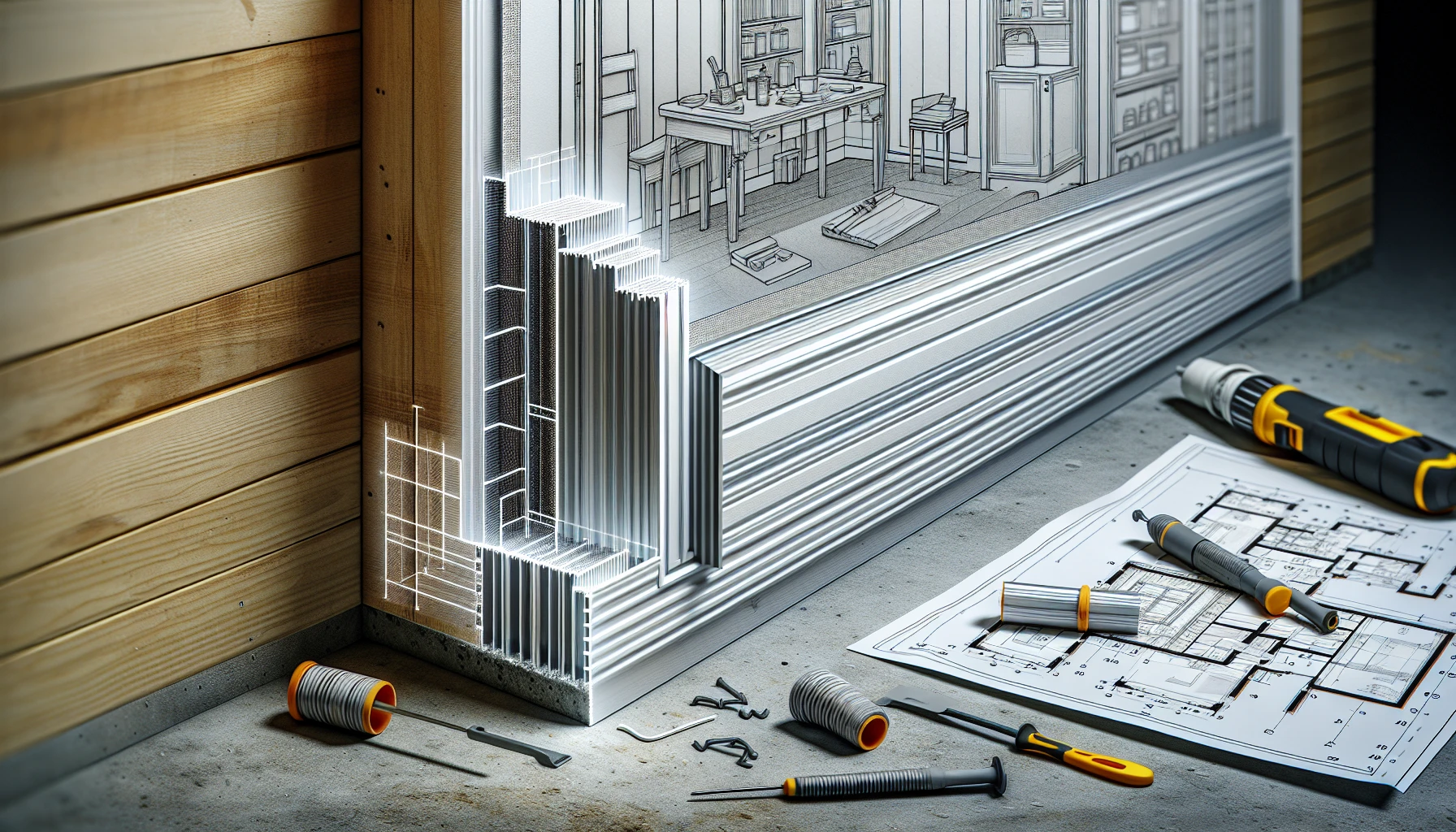

Laying the Groundwork with Starter Strips and Flashing

Installing the starter strip for vinyl siding

Initiating the process with starter strips and flashing is a primary step in vinyl siding installation. Ensuring a solid foundation will help guarantee a smooth and long-lasting installation that protects your home from the elements.

Installing the Starter Strip

The starter strip serves as a reliable foundation for siding panels and should be installed at the base of the wall, no less than 8 inches above ground level. To install the starter strip, follow these steps:

- Use a chalk line to set course lines level and snap a line for the starter strip.

- Place a nail in the original mark and hook a string line onto it.

- Pull the string line through the reference mark and snap it, creating a level chalk line for the first starter strip.

By adhering to these steps, the starter strip can be ensured to be level and properly installed.

After installing the starter strip, adhering to the applicable regulations during the installation of siding panels is important. Here are the steps to follow:

- Secure each length of siding in position, ensuring that its lower lip is hooked beneath the starter strip.

- Slide the item into the corner and secure its position with fasteners every 16 inches.

- This will ensure that it is properly held in place.

Applying Flashing

Application of flashing around windows, doors, and corners is critical in preventing water infiltration. Aluminum or vinyl flashing are recommended for vinyl siding installation. To ensure proper installation of flashing, follow these steps:

- Cut pieces of building paper and self-adhesive flashing to match the dimensions of the window or door.

- Install the flashing in the correct order, beginning with the bottom and then the sides.

- Make sure that the flashing tape on the sides and bottom overlaps the building wrap.

- Press the flashing into the sealant bead at the bottom edge of the existing window.

With the starter strips and flashing properly installed, you’re ready to move on to the main event – installing the siding panels.

Installing Panels: The Main Event

Precision cutting of vinyl siding panels

The fundamental part of vinyl siding installation is the installation of siding panels. This stage involves cutting techniques, attaching the siding panel, and ensuring proper alignment and overlap.

With the right tools and techniques, you’ll achieve a polished and professional look for your home’s exterior.

Cutting Techniques with Tin Snips and Utility Knife

Tin snips, a utility knife, and a snap lock punch tool are essential tools for cutting vinyl siding panels accurately and efficiently. To use tin snips to cut vinyl siding, follow these steps:

- Mark the cutting line on the siding using a pencil or marker.

- Hold the tin snips with a firm grip and position the blades along the marked line.

- Apply steady pressure and make a smooth, continuous cut along the line.

- Be careful not to apply too much force, as it may cause the vinyl siding to crack or break.

For straight cuts, the score and snap method using a utility knife is the most efficient technique for cutting vinyl siding. Here’s how to do it:

- Score the siding with the utility knife along the line where you want to make the cut.

- Apply pressure to the scored line to snap the siding along the score.

- Repeat the process for any additional straight cuts you need to make.

This method is both quick and simple, especially for straight cuts.

Attaching Siding Panels

After cutting the siding panels, they can now be attached. To install vinyl siding panels, follow these steps:

- Choose corrosion-resistant fasteners such as aluminum and galvanized steel nails, staples, or screws.

- For horizontal siding panels, space the nails, screws, or staples a maximum of 16 inches apart.

- For vertical siding panels, space the nails, screws, or staples every 12 inches.

When attaching siding panels, it’s essential to take into account the potential for expansion and contraction due to changes in temperature and humidity. If this is not done, it may lead to buckling, warping, or other damage. To ensure proper installation, it is recommended to use a fastening system that allows for movement and to attach the panels to the studs, rather than just the sheathing.

Ensuring Proper Alignment and Overlap

Correct alignment and overlap of siding panels are important in warding off water infiltration and keeping a tidy appearance. Here are some tips for ensuring proper alignment when installing vinyl siding panels:

- Measure carefully before installing starter strips and corner posts.

- Use spacers or shims during installation to ensure the correct spacing and alignment.

- Employ a string line to create a straight line between two reference points.

- Check the horizontal alignment of the panels every few rows to ensure they are hanging straight and level on the wall.

By following these steps, you can achieve a professional-looking installation and prevent water damage.

By ensuring proper alignment and overlap, your vinyl siding installation will not only look polished but also provide long-lasting protection for your home.

Mastering the Tricky Parts: Soffit and Fascia

Installing vinyl soffit and fascia

Although the installation of soffit and fascia can be challenging, mastering these aspects will result in a refined and professional look for your vinyl siding project.

Proper installation of soffits and fascia covers not only enhances the appearance of your home but also helps protect it from water damage.

Installing Vinyl Soffit

Vinyl soffit installation requires attention to detail and the use of J-channels and F-trim for a secure and seamless fit. To install a J-channel for vinyl soffit, follow these steps:

- Measure and cut the J-channel to the desired length.

- Position the J-channel along the edge of the soffit area, ensuring it is level and plumb.

- Attach the J-channel to the wall or fascia board using nails or screws.

- Leave a small gap between the fasteners to allow for expansion.

Insert the vinyl soffit panels into the channels, starting from one end and working your way across. Ensure the soffit panels are securely seated in the J-channels, but allow for some movement to accommodate expansion and contraction. Be cautious of any loose boards that may cause instability during the installation process.

Securing Fascia Installation

Securing fascia installation is crucial for a polished appearance and protection from the elements. To attach fascia to the soffit, follow these steps:

- Use nails or screws to fasten the fascia to the soffit, ensuring a secure attachment.

- Slide preformed lengths of fascia cover under the gutter apron.

- Secure the upper portion of the fascia with 4D galvanized or pre-painted nails.

Ensuring a secure fascia installation will not only improve the appearance of your home but also help protect it from water damage.

Finishing Touches: Trim and Detail Work

Sealing and caulking for vinyl siding trim

The finishing touches of your vinyl siding installation include window and door trim as well as sealing and caulking. These final steps will complete the polished appearance of your home and ensure its protection from the elements.

Window and Door Trim

Installing window and door trim using trim channels and proper cutting techniques will give your vinyl siding project a seamless and professional appearance. Here’s how to do it:

- Cut the top channel two inches longer than the window or door width when installing window and door trim. Use the excess to create drip edges.

- The back of the channel should be cut flush and the facing edge should be allowed to run long.

- Set the channel in place and secure it.

- Trim the excess from the facing edges.

By following these steps, you can achieve a clean and polished look for your window and door trim.

Properly installed trim will not only enhance the appearance of your home but also provide added protection against water infiltration.

Sealing and Caulking

Sealing and caulking are essential for preventing water infiltration and ensuring a clean finish. Use a high-quality, moisture-resistant sealant to caulk all trim and seams around windows, doors, and corners.

It is recommended to use polyurethane or another UV-resistant sealant for vinyl siding. Proper sealing and caulking will not only improve the appearance of your home but also provide a long-lasting, protective barrier against water infiltration.

Addressing Expansion and Contraction

Addressing expansion and contraction is a crucial aspect of vinyl siding installation. Proper nail placement and utility trim installation will allow for the natural movement of the siding with changes in temperature, reducing the risk of warping or buckling.

Nail Placement and Technique

Appropriate nail placement and technique are essential for allowing the expansion and contraction of vinyl siding. Here are some guidelines to follow:

- Center the nails in the nailing slots of the siding.

- Drive the nails loosely, penetrating at least 3/4 inch into the wood sheathing.

- Utilize two nails per square of vinyl siding, with one placed at the top and the other at the bottom.

Proper nail placement will ensure a secure and long-lasting siding installation.

Installing Utility Trim

Installing utility trim is vital for securing the last piece of siding and accommodating expansion and contraction. Install the trim prior to cutting the top row of siding, and use it to provide a space for the siding to move, accommodating for natural expansion and contraction due to temperature changes.

Proper utility trim installation will ensure a secure and flexible connection between the siding and the eave, protecting your home from potential damage.

Custom Fitting: Working Around Obstacles

Custom fitting your vinyl siding around obstacles such as faucets and utility equipment ensures a seamless and professional appearance. Cutting and fitting around these obstacles, as well as using J-channel and utility trim, will provide a clean and polished finish.

Cutting and Fitting Around Protrusions

Cutting and fitting siding around protrusions such as faucets and utility equipment can be challenging but is essential for a seamless installation. To cut vinyl siding around such obstacles, follow these steps:

- Measure the angle of the cut.

- Transfer the angle measurement onto the siding.

- Use a utility knife or tin snips to make the angled cut along the marked line.

- Test the fit of the cut piece on the obstacle.

Properly cut and fitted siding will ensure a polished and professional appearance.

Using J-Channel and Utility Trim

Using J-channel and utility trim to secure siding around obstacles will provide a clean and polished appearance. Install J-channel around windows, doors, and other openings by nailing it to the wall, leaving a small gap for expansion.

Insert the vinyl siding panels into the channels, ensuring they are snug and properly aligned. Proper use of J-channel and utility trim will guarantee a secure and seamless vinyl siding installation.

Advanced Techniques: Complex Angles and Corners

Mastering advanced techniques for complex angles and corners will elevate your vinyl siding installation. Corner post installation and angled cuts for gables will ensure a polished and professional look for your home’s exterior.

Corner Post Installation

Corner post installation is an essential part of a polished and professional vinyl siding project. To ensure proper corner post installation, follow these steps:

- Install the corner post above the roofline to prevent water infiltration.

- Apply a thin bead of caulk along the edges of the corner post to create a watertight seal.

- Install the post level and plumb, ensuring it is straight and vertical.

- Nail the corner post securely to the wall.

By following these steps, you can ensure a proper and secure installation of the corner post.

Proper corner post installation will not only enhance the appearance of your home but also protect it from water damage.

Angled Cuts for Gables

Making angled cuts for gables is an advanced technique that ensures a clean appearance and proper fit with the slope of the roof. To make angled cuts in vinyl siding for gables, follow these steps:

- Measure the angle of the gable using a protractor or angle finder.

- Transfer the angle measurement onto the vinyl siding using a square or a straight edge.

- Use a utility knife or tin snips to make the angled cut along the marked line.

- Test the fit of the cut piece on the gable and make any necessary adjustments.

Properly cut and fitted gable siding will ensure a polished and professional look for your home’s exterior.

Cleanup and Maintenance Tips

Proper cleanup and maintenance of your vinyl siding will ensure its longevity and appearance. Regular cleaning and inspections can help identify and address any potential issues, keeping your home’s exterior looking its best.

Post-Installation Cleanup

Upon completion of the vinyl siding installation, cleaning up debris and appropriately disposing of old siding and materials is important. Utilize a soft cloth or soft-bristled brush and a mixture of soap and water to clean the newly installed siding without causing damage.

Dispose of old siding materials according to local building codes and consider recycling options available for certain materials, such as vinyl siding.

Long-Term Care for Vinyl Siding

For maintaining the durability and appearance of your vinyl siding, regular cleaning and inspections are required. Here are some steps to follow:

- Clean vinyl siding every 2 to 3 years using a soft-bristled brush or a soft microfiber cloth and a mixture of soap and water or a specialized cleaning solution.

- Inspect your siding for signs of damage, such as cracking, warping, or fading.

- Address any issues promptly to prevent further damage.

With proper care and maintenance, your vinyl siding will continue to look great and protect your home for many years to come.

Summary

In this comprehensive guide, we’ve covered the essential steps and techniques for a flawless vinyl siding installation. From preparing your home and laying the groundwork to mastering soffit and fascia installation, custom fitting, and advanced techniques for complex angles and corners, you now have the knowledge to transform your home’s exterior. With proper care and maintenance, your vinyl siding will provide lasting beauty and protection for your home.

Frequently Asked Questions

Can I install vinyl siding myself?

Although installing vinyl siding by yourself might save you money, it requires time, skill, and knowledge of the process. To succeed, you should have complete installation instructions, as well as a few tools like a zip tool, circular saw, and pry bar. However, if you’ve never installed vinyl siding before, it is probably best to hire a contractor.

What is the most common mistake when installing vinyl siding?

The most common mistake when installing vinyl siding is not leaving the correct amount of overlap between panels; the industry standard is 1-1.25 inches.

What do you put under vinyl siding?

Underlayment or weather-resistive barrier should be installed between the siding and sheathing, such as tar paper, HardieWrap®, or Tyvek HomeWrap®.

Do you nail vinyl siding starter strip tight?

For successful installation, it’s important to not nail your vinyl siding starter strip too tightly against sheathing. Keep the nail heads proud of the vinyl so that the vinyl can move freely in the installation slots.

How do you install vinyl siding for beginners?

To install vinyl siding, start by nailing J-channel pieces under the fascia, followed by installing soffit pieces and the starter strip. Then, measure the walls, install corner posts, and finish up by installing J-trim around doors and windows.